Fermenting Beer with White Labs WLP300 Hefeweizen Ale Yeast

Published: December 1, 2025 at 8:49:53 PM UTC

White Labs WLP300 Hefeweizen Ale Yeast is a top choice for brewers aiming for authentic German wheat flavors. It creates the distinctive banana ester and subtle clove phenol that are hallmarks of the style.

The yeast's low flocculation ensures the beer retains its traditional haze. Its 72–76% attenuation and moderate alcohol tolerance also contribute to a predictable body and finish.

This review of WLP300 draws from White Labs' specifications, community feedback, and practical brewing insights. Whether you're brewing hefeweizen for the first time or refining a recipe, understanding pitching rate, temperature control, and oxygenation is crucial. These factors significantly influence the beer's aroma and flavor. The article will guide you through these variables to achieve consistent results with this German wheat yeast.

Key Takeaways

- WLP300 delivers classic banana-forward hefeweizen character with balanced clove phenols.

- Low flocculation preserves haze; expect 72–76% attenuation and medium–high alcohol tolerance.

- Fermentation temperature and pitching rate are the main levers to tune esters and phenols.

- Use measured oxygenation and proper vessel choice to get consistent fermenting hefeweizen results.

- This WLP300 review consolidates manufacturer data and brewer experience for practical guidance.

Understanding White Labs WLP300 Hefeweizen Ale Yeast

WLP300 is a classic German hefeweizen strain, celebrated for its lifted fruit-phenolic balance. The strain's profile showcases strong ester production, with a signature isoamyl acetate banana aroma. This aroma is a hallmark many brewers aim for in traditional wheat beers.

Alongside the banana esters, clove phenols emerge as 4-vinyl guaiacol, adding a gentle spicy backbone. Brewers often note that clove phenols are present but usually take a backseat to the isoamyl acetate banana. This is especially true when fermentation runs warm or the yeast is underpitched.

Attenuation for WLP300 falls in the 72–76% range, ensuring a creamy, full wheat mouthfeel. This attenuation range is crucial for maintaining head retention and the soft, billowy texture expected in hefeweizen and weizenbock recipes.

Flocculation is low, which means haze remains in the finished beer. This low flocculation ensures yeast stays suspended, preserving both esters and the traditional cloudy appearance of unfiltered hefeweizens.

The strain can handle moderate to high alcohol levels, typically around 8–12%. However, performance can be stressed near the upper limit. WLP300 is STA1 negative, meaning it does not over-attenuate worts with adjunct enzymes. This characteristic helps predict final gravity when using dextrinous grain bills or candi syrups.

- Primary flavor drivers: isoamyl acetate banana and clove phenols.

- Fermentation behavior: low flocculation and predictable attenuation.

- Practical tip: warmer fermentations or lower pitch rates emphasize banana esters.

Why Choose White Labs WLP300 Hefeweizen Ale Yeast for Your Brew

WLP300 is specifically designed for Weissbier and weizenbock styles. This makes it a top choice for brewers aiming for a genuine German flavor. It offers a banana-forward ester core with balanced clove phenolics, aligning perfectly with the classic Hefeweizen and other wheat beers.

The yeast's low flocculation ensures the beer remains hazy. This characteristic is crucial for maintaining the authentic German wheat character. Brewers often underpitch or ferment slightly warmer to enhance isoamyl acetate and traditional aromas.

WLP300 is remarkably versatile across different strengths. It can be used in low-gravity Kristalweizen, which can be cold-conditioned for clarity, or in higher gravity weizenbock recipes up to its alcohol tolerance. This makes it an excellent choice for those seeking consistent results in their brewing.

White Labs makes WLP300 widely available, including Pure Pitch Next Gen packaging and an organic option. This broad availability ensures that both homebrewers and professional breweries can easily find a reliable Weissbier yeast.

- Flavor profile: banana esters with clove phenolics.

- Appearance: low flocculation maintains traditional haze.

- Versatility: suitable for any wheat beer from Kristal to weizenbock.

- Availability: common retail and specialty packaging options.

Recommended Fermentation Temperature Range for WLP300

White Labs suggests the perfect WLP300 fermentation temperature is 68–72°F (20–22°C). This range allows the yeast to produce classic fruit and clove notes. It prevents harsh phenolics from dominating the flavor.

The fermentation temperature significantly influences ester production and phenolic balance. It's crucial during the lag phase and active growth. This is when yeast multiply and many esters form.

Brewers who ferment slightly warmer than 72°F or underpitch may notice more banana-like character. This is due to increased isoamyl acetate production. On the other hand, cooler fermentations, closer to 68°F, result in cleaner profiles and faster settling of particulates.

Community trials indicate that cooler fermentation temperatures enhance clarity. Trub and proteins bind and drop out more effectively. Warmer ferments, while cloudier, can boost ester production and aroma.

To achieve a Kristalweizen-style finish, some brewers cold-condition at near 32°F after attenuation. This retains the hefe character while improving clarity. Maintaining careful temperature control, especially early, is key. It ensures the best balance of banana, clove, and mouthfeel for WLP300.

Pitching Rate and Its Impact on Flavor

The WLP300 pitching rate significantly influences the production of esters and phenols in hefeweizen. Brewers who underpitch their hefeweizen often notice a more pronounced banana-like ester presence. This results in a fuller, more traditional aroma. White Labs explains that the cell count at the time of pitching affects how the yeast metabolizes sugars and produces volatile compounds.

Opting for a pure pitch from White Labs' Pure Pitch Next Gen vials can lead to a slight underpitch for various wort gravities. This modest underpitch can enhance the classic hefe profile without the need for additional intervention. Many homebrewers employ this strategy to achieve a more pronounced banana and clove presence in their beers.

Creating a yeast starter can increase cell numbers and shorten the lag phase. A robust yeast starter can reduce ester formation, steering the beer towards a cleaner profile. This approach is ideal when clarity and a muted ester profile are the desired outcomes.

The choice of pitching strategy must align with oxygenation levels. Lower pitch rates typically require conservative oxygen levels to prevent unwanted sulfur or phenolic off-notes. Conversely, higher pitch rates necessitate adequate oxygen to support biomass and ensure a healthy, even fermentation.

- Low pitch: favors ester production; consider careful oxygen control.

- Pure pitch: often mimics traditional underpitching with WLP300.

- High pitch or starter: shortens lag phase and yields cleaner flavors.

Striking a balance between your desired flavor and the process requirements is crucial. For bold banana esters, consider underpitching or using a pure pitch. If you prefer a more restrained flavor, create a yeast starter and ensure proper oxygenation. This will help maintain a clean and stable flavor profile.

Oxygenation and Its Role with WLP300

Dissolved oxygen at pitch is crucial for WLP300 performance. Proper oxygenation supports strong cell membranes, reduces lag time, and aids in clean sugar conversion. This is vital for the yeast's health and efficiency.

For large starters or high pitch rates, standard aeration is key. It ensures cells get enough oxygen before fermentation starts. This approach minimizes yeast stress and prevents sulfur and other off-flavors.

Some brewers prefer low O2 hefeweizen builds to enhance ester and phenol expression. By limiting aeration and underpitching, the growth phase is extended. This boosts banana and clove flavors.

It's important to avoid adding oxygen after the first signs of fermentation. Late oxygen can reactivate yeast, leading to oxidation or unwanted flavors. Aerate only before pitching and handle transfers carefully.

Match oxygenation WLP300 to your pitching plan:

- If pitching a fresh large starter, use full aeration for wheat yeast to support quick, healthy fermentation.

- If aiming for ester-forward O2 hefeweizen with intentional underpitching, reduce initial oxygen to favor flavor development.

- When repitching harvested yeast, monitor cell counts and adjust aeration accordingly to avoid under- or over-oxygenation.

Control aeration for wheat yeast with a calibrated aeration stone or measured shaking for small batches. Keep records of dissolved oxygen and outcomes. This helps refine techniques for WLP300 across different recipes and scales.

Fermentation Geometry and Vessel Considerations

The role of fermentation geometry in White Labs WLP300's ester and phenol expression is subtle yet significant. Headspace, vessel wall surface, and CO2 flow impact yeast contact with trub and gas exchange. Even minor changes in geometry can significantly alter the sensory profile of wheat beers.

When selecting equipment, consider the fermentor shape for your hefeweizen. Tall, narrow vessels facilitate faster gas venting, potentially reducing yeast suspension. Conversely, wide, shallow vessels allow more yeast to remain suspended, enhancing ester production. The choice between these shapes depends on the desired flavor profile for your hefeweizen.

The decision between conical and bucket fermenters hinges on workflow and flavor objectives. Conical fermenters streamline yeast harvesting and trub removal, leading to a cleaner beer with less phenolic residue. Buckets, on the other hand, are ideal for open or semi-open fermentations, aiming to preserve traditional hefe characteristics.

Open versus closed fermentation impacts phenolic and ester development. Open vessels facilitate mild oxygen interaction and volatile escape. Closed systems, however, retain CO2 and esters, altering the aromatic balance. Brewers seeking classic Bavarian notes often favor more open fermentation methods.

- Vessel considerations for transfers: minimize splashing to limit oxygen pickup during moves from brew kettle to fermenter or from bright tank to packaging.

- Conical vs bucket choice: use conicals for easy yeast management, buckets for simple, open fermentation trials.

- Fermentor shape hefeweizen: test narrow and wide geometries to hear the difference in ester/phenol balance.

Consistent temperature, alongside geometry, is crucial for repeatable results. Insulated vessels that maintain a temperature range of 68–72°F reduce hotspots and unpredictable yeast responses. Geometry that supports even thermal mass enhances fermentation control, making WLP300's character more predictable.

Practical considerations for vessels include cleaning access, sampling ease, and the ability to cold crash or harvest yeast. Each factor influences the final profile of a WLP300 hefeweizen. Brewers should test one change at a time to isolate the effects of fermentation geometry WLP300 and equipment choices.

Water and Mash Profile Tips to Enhance WLP300 Characteristics

Begin with a water profile that's neutral to moderately hard. This allows WLP300 to showcase its banana and clove notes. Aim for calcium levels of 50–100 ppm to enhance enzyme activity and head retention. Avoid sulfate-driven bitterness. If you're using a heavy wheat grist, adjust bicarbonate levels accordingly.

Your mash schedule should align with your desired mouthfeel. A mash temperature of 154–156°F will result in a fuller body, enhancing the traditional hefeweizen character. Conversely, a lower saccharification temperature will yield a drier beer, potentially altering the presentation of esters in the final product.

Consider using a decoction for hefe to enrich malt aroma and wheat complexity. A one-third single decoction boiled hard can add caramelized notes and elevate wheat-forward aromas. This method maintains fermentability similar to a single infusion mash.

To emphasize phenolic clove, incorporate a short ferulic acid rest at 113°F (45°C). Briefly hold the rest before increasing the temperature for saccharification. The intensity of 4-vinyl guaiacol can vary among strains. Small batch testing is essential to understand WLP300's response.

The Herrmann-Verfahren involves enzymatic steps to convert maltose to glucose, potentially influencing ester formation. This method is experimental and not commonly adopted by homebrewers.

Here are practical tips for planning your mash:

- For classic mouthfeel, aim for 154–156°F mash and a gentle mashout.

- If you want more clove, add a short ferulic acid rest near 113°F before saccharification.

- Try a modest decoction for hefe to enhance wheat character without over-thickening the wort.

- Reserve the Herrmann-Verfahren or enzymatic conversions for test batches to see if altered sugar profiles shift ester balance.

Keep detailed records of water adjustments, mash temperatures, and timing. Even small changes can significantly impact WLP300's aroma and flavor. Consistent notes will help refine your mash profile and brewing techniques over time.

Fermentation Timeline and Monitoring with WLP300

Early activity is key for shaping esters and phenols. The WLP300 fermentation timeline starts with inoculation, followed by a lag phase. This phase's duration depends on the pitch rate and oxygen levels. Most brewers see fermentation kick in at 68–72°F for several days. It's crucial to check gravity daily until the decline becomes steady.

Keep an eye on aroma and krausen, alongside gravity. Yeast-derived esters and phenols form during the lag and active growth phases. Catching these stages allows you to steer the flavor towards classic hefe notes or a cleaner profile.

- Day 0–2: lag, aroma development; adjust temperature and oxygen if needed.

- Day 3–7: active fermentation; primary attenuation occurs here.

- Day 7–14: conditioning for flocculation and flavor maturation.

For clarity goals, a post-primary rest is essential. Hefeweizen conditioning benefits from a few days of gentle conditioning at fermentation temperatures. This patience reduces yeast-driven off-notes and polishes the profile.

A Kristal-style approach involves cold steps. Cold conditioning Kristalweizen at about 32°F for roughly one week after conditioning clarifies while preserving core yeast flavors. Cooler temperatures speed up particle settling, enhancing visual clarity.

Decide when to rack or keg based on stable gravity and aroma. Transfer after fermentation has stabilized to avoid autolysis and control carbonation. Record readings and tasting notes to refine your WLP300 fermentation timeline for future batches.

Managing Clarity While Keeping Traditional Hefe Character

WLP300 is celebrated for its soft, pillowy haze. However, brewers often seek control over this cloudiness. Cold conditioning at near-freezing temperatures aids in settling suspended proteins and yeast. This method preserves ester and phenol expression without sacrificing clarity.

Many brewers employ Kristalweizen cold conditioning steps. For instance, holding the beer at about 32°F for a week. This approach enhances clarity while maintaining banana and clove notes.

Temperature during fermentation plays a crucial role in haze management WLP300. Cooler temperatures encourage tighter particle binding and faster settling. If you ferment warmer to emphasize esters, consider a longer conditioning or an extra racking to regain clarity.

Fining agents and filtration can significantly improve clarity. However, they also alter mouthfeel and aroma. Kieselsol and gelatin effectively remove yeast and protein haze. Filtration, on the other hand, can result in a lager-like finish but diminishes the classic hefe character. The choice between appearance and traditional cloudiness depends on the desired drinking experience.

To create a beach-ready Kristalweizen, aim for a lower original gravity and a clean mash profile. Cold-condition after fermentation and carbonate gently to retain delicate esters. This method produces a clear, refreshing beer that preserves the core flavors of WLP300.

- Time racking to leave coarse lees behind and protect aroma.

- Cold crash before packaging to accelerate particle drop-out.

- Control carbonation to avoid re-suspending fines.

The goal is to find a balance: a modest haze for traditional presence or a clear Kristalweizen finish through cold conditioning and careful process control. Thoughtful haze management WLP300 ensures the sensory profile remains true to style while meeting drinker expectations for clarity.

Alcohol Tolerance and Recipe Considerations

WLP300's alcohol tolerance is generally around 8–12% ABV. This range is ideal for fermenting classic hefeweizens and supports the creation of stronger weizenbock yeast blends up to the upper limit.

When brewing a high gravity wheat beer, it's crucial to monitor the original gravity. This ensures the yeast can handle the load. Attenuation levels of 72–76% provide a balanced finish. Adjust the mash profile and fermentables to achieve the desired body and final gravity without overtaxing the yeast.

For brews with ABV approaching or exceeding 10–12%, employ staged techniques to ease yeast stress. Step-feeding simple sugars, adding yeast nutrients in intervals, or using an active starter can prevent stuck fermentation and reduce solvent-like esters.

Keep a close eye on yeast health in stronger brews. Adequate oxygenation at pitching and a robust starter enhance early growth. Staggered nutrient additions and temperature control during active fermentation support clean attenuation and reliable performance.

WLP300 is STA1 negative, meaning it won't over-attenuate adjunct-rich worts like STA1+ strains do. This is important when adding sugars or dextrose to ensure your final gravity and mouthfeel align with your recipe goals for a weizenbock yeast beer or other high gravity wheat beer.

- Target OG to match desired ABV while staying below 12% when possible.

- Use starters and oxygenation for strong pitches.

- Step-feed or add nutrients for high gravity fermentation.

- Adjust mash and adjuncts knowing STA1 negative behavior.

Common Off-Flavors and Troubleshooting with WLP300

WLP300 off-flavors often manifest as excessive clove or solvent notes, resulting from suboptimal fermentation conditions. A pronounced clove flavor can arise from high wort phenolic content, warm fermentation temperatures, or inappropriate mash pH. It's crucial to monitor temperature closely to maintain a balance between phenols and esters.

Undersized yeast cakes increase the likelihood of banana ester issues and stressed fermentation. Underpitching can enhance banana character, which some brewers desire. However, extreme underpitching can lead to prolonged lag phases, stressed yeast, and solventous fusel alcohols. Adjust the pitch rate accordingly to match the beer's gravity and desired ester level.

Insufficient oxygen or nutrients frequently causes sluggish activity and off-flavors in high-gravity kits. Ensure a measured oxygen dose at pitch and consider adding yeast nutrient for large beers. Proper oxygenation minimizes the risk of solventous notes and ensures predictable fermentation kinetics.

Temperature fluctuations can alter the strain's balance of phenols and esters. Warmer temperatures can intensify banana ester issues while sometimes increasing phenolic clove character. Maintain fermentation within White Labs' recommended range and make small, deliberate adjustments for desired banana or clove levels.

Sanitation and post-fermentation handling are critical for flavor stability. Avoid oxygen exposure after active fermentation, monitor krausen and terminal gravity to gauge yeast health, and minimize time on yeast to prevent autolysis. These practices reduce the risk of cardboard, oxidation, and other off-flavors.

- Check pitch rate vs. original gravity to prevent stress.

- Measure dissolved oxygen at pitch when possible.

- Hold fermentation temperatures steady inside the target range.

- Use yeast nutrient for high-gravity or extended fermentations.

- Sanitize well and limit post-fermentation oxygen exposure.

When troubleshooting hefeweizen, keep detailed sensory notes as you adjust variables one at a time. Record temperature, pitch size, oxygen added, and gravity curve to understand how WLP300 behaves in your system. Small, controlled changes lead to consistent results and help minimize unwanted clove off-flavor or banana ester issues.

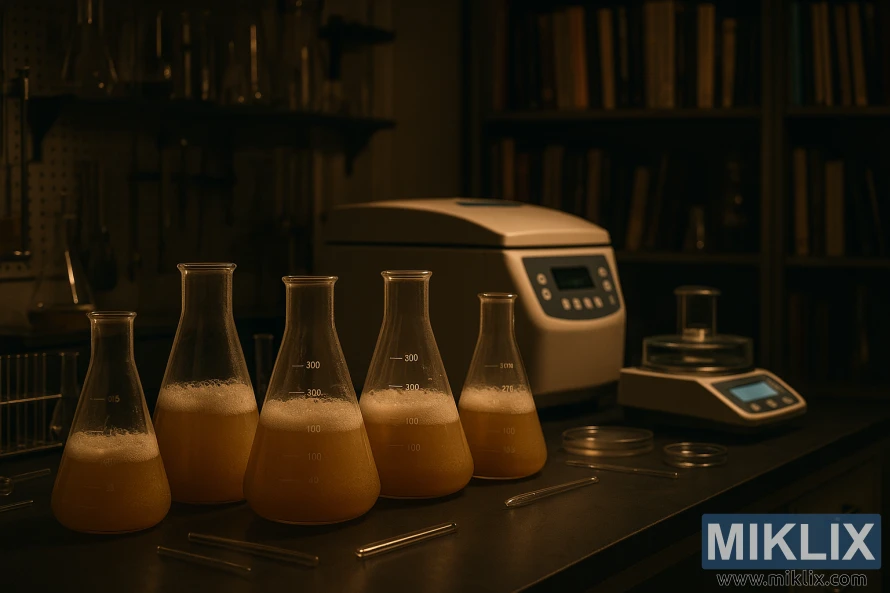

Practical Brewing Experiments to Tune WLP300 Performance

Design short, repeatable trials to isolate single variables when running WLP300 experiments. Keep batches small and ingredients consistent to reduce noise between runs.

Focus on three core sets of trials: pitch rate experiments, temperature variation, and mash method changes. Each set should test one factor while holding others steady.

- Pitch rate experiments: compare underpitch (30–40% of standard cells) versus a full standard pitch. Record cell counts, viability, and oxygenation method for each trial.

- Temperature studies: brew paired batches at cool (68°F) and warm (72–74°F) fermentation profiles. Log peak activity, duration, and fermentation vessel type.

- Mash and phenolic trials: run a partial decoction versus single-infusion mash and include a ferulic acid rest to probe 4VG and clove expression.

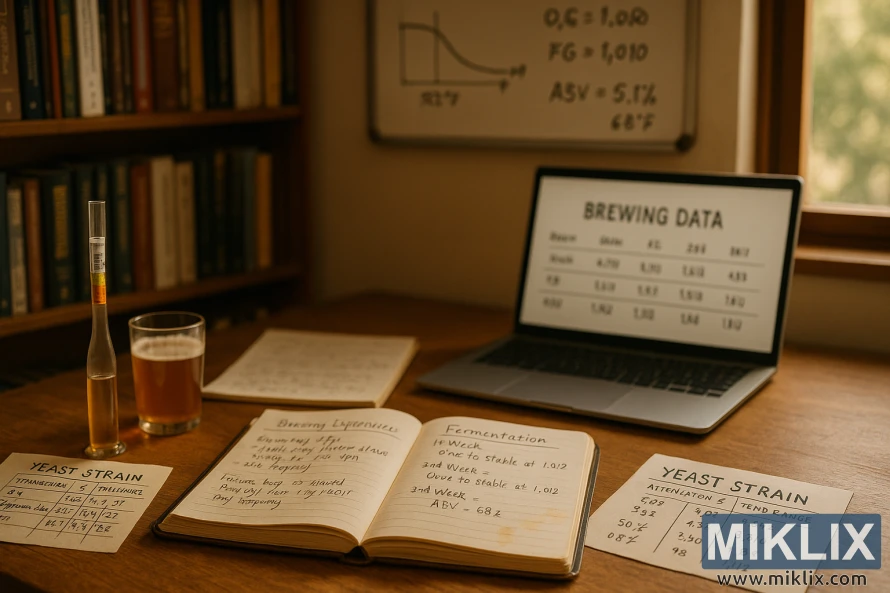

Document every detail. Note starting gravity, attenuation, oxygen ppm, yeast starter size, and vessel geometry. Good records let you compare across hefeweizen brewing tests with confidence.

Use randomized sensory protocols to cut bias. Employ triangle tests, cup color randomization, and randomized serving order during hefeweizen brewing tests to get reliable feedback from tasters.

- Plan: define the single variable and expected sensory markers.

- Execute: brew matched pairs, control ambient conditions, and use the same water profile.

- Record: keep a log of all numeric values and qualitative notes.

- Evaluate: conduct blind tastings and compile scores for aroma, esters, phenolics, and overall balance.

Repeat promising trials to confirm trends. Community reports show WLP300 experiments reveal higher sensitivity to pitch and temperature than many ale strains, making repetition valuable.

Keep results organized for meta-analysis. Combine data from multiple runs to spot consistent shifts in ester or phenolic expression across pitch rate experiments and other variables.

Packaging, Carbonation, and Serving Suggestions for WLP300 Beers

When selecting WLP300 packaging, consider the finish you aim for. Kegging offers precise control over carbonation and allows for quick yeast removal. On the other hand, bottle conditioning maintains a live yeast character, resulting in some sediment and haze.

For hefeweizen, aim for 2.5–3.0 volumes CO2 to enhance banana and clove notes and improve head retention. If kegging, set CO2 levels and allow for slow carbonation over a week. For bottles, prime with sugar and warm condition to reach the desired carbonation levels.

Kristalweizen packaging benefits from cold-conditioning and filtration or careful fining to reduce haze. Cold-crashing in the fermenter, racking clear beer to a keg, or filtering can produce a brighter pour while preserving core aromatics.

Serving hefeweizen at 45–55°F is ideal. This temperature range allows esters and phenols to shine without being overpowered by chill. Pour into a tall weizen glass to enhance color, carbonation, and a tall, creamy head that traps aroma.

- Glassware: tall weizen glass concentrates aroma and shows off hefe character.

- Kegging: precise hefeweizen carbonation control and fast removal of yeast haze.

- Bottle conditioning: preserves yeast-driven flavor and traditional haze.

- Kristalweizen packaging: use conditioning and cold-crash to reduce yeast in the bottle or keg.

In planning WLP300 packaging, aim for a balance between clarity and character. Those desiring a bright beer will opt for Kristalweizen steps. Brewers preferring a classic wheat texture will favor bottle conditioning and a slightly higher final gravity to maintain mouthfeel and yeast presence.

Where to Buy and Product Options for WLP300

White Labs lists WLP300 Hefeweizen Ale Yeast on its product pages. It provides details on attenuation, flocculation, alcohol tolerance, and suggested fermentation range. For a White Labs WLP300 purchase, check the official site and authorized distributors across the United States. They offer stock and regional shipping notes.

Pure Pitch Next Gen vials are a common format for homebrewers. These single-dose vials simplify pitching for standard 5-gallon batches. However, if you plan to brew higher gravity beers, a starter is necessary. Pure Pitch Next Gen can underpitch heavier worts.

White Labs offers an organic option of this strain. The WLP300 organic variant appears on select retailer lists and on White Labs' catalog. Seek it out if certified organic ingredients matter for your brew.

- Local homebrew shops often carry WLP300 and can advise on storage and handling.

- Online retailers feature customer reviews and Q&A sections that help with purchase decisions.

- White Labs sometimes includes batch satisfaction guarantees and free shipping promotions above set order totals.

When you buy WLP300, match vial choice to batch gravity and volume. A Pure Pitch Next Gen vial works well for many ales. However, consider creating a starter for big or high-OG recipes.

Before any White Labs WLP300 purchase, verify shipping conditions. Cold chain handling helps preserve yeast viability. If you need WLP300 organic, confirm certification with the seller.

Real-World Brewer Notes and Community Findings

Homebrewers trading WLP300 community notes often report a strong banana presence from isoamyl acetate. Many say the 4-vinyl guaiacol (clove) level shifts with small changes in process. Variable results show how pitching rate, fermentation temperature, mash schedule, and oxygenation shape the final aroma.

Groups comparing hefeweizen homebrew experiences describe two common approaches. One group underpitches and ferments warm to boost banana esters. A second group uses decoction mashes or ferulic rests to lift phenolic clove character. Both methods produce different WLP300 tasting notes that reflect intent.

Community experiments emphasize that German wheat strains respond more to handling than many American or English ale yeasts. Small changes to oxygenation and pitching rate often alter ester-to-phenol balance. Brewers note this sensitivity when aiming for classic hefeweizen traits.

- Triangle testing appears often in organized tastings to reduce bias.

- Presenters randomize cup order while keeping cup color consistent.

- Tasters record which sample shows banana, clove, or neutral profiles.

Reports on clarity vary. Some brewers cold-condition low-gravity hefe to make Kristalweizen, while others accept haze as part of the style. WLP300 tasting notes from both camps help new brewers set expectations before brewing.

Recorded hefeweizen homebrew experiences in forums and local clubs form a useful database. These practical notes guide adjustments for ester control, desired phenolic lift, and preferred haze level. Reading broad community feedback can speed learning for brewers working with WLP300.

Conclusion

White Labs WLP300 emerges as a reliable choice for Weissbier and Weizenbock. It offers a classic banana-forward ester profile, balanced clove phenolics, and the signature haze from low flocculation. This review concludes that predictable results come from treating pitching rate, fermentation temperature, oxygenation, and mash regimen as interconnected factors.

To achieve consistent outcomes, adhere to a 68–72°F fermentation range. Consider modest underpitching to enhance ester production. Match oxygenation and nutrients to gravity for stronger beers within WLP300’s 8–12% tolerance. Practical brew tips include testing one variable at a time and using randomized tastings to fine-tune isoamyl acetate versus 4VG balance.

WLP300 is available in PurePitch NextGen vials and an organic option. Combining manufacturer specs with community notes enhances repeatability. In conclusion, disciplined experimentation and intentional recipe choices will yield authentic, reproducible German wheat beers. These showcase WLP300’s strengths.

Further Reading

If you enjoyed this post, you may also like these suggestions:

- Fermenting Beer with CellarScience Voss Yeast

- Fermenting Beer with Lallemand LalBrew Diamond Lager Yeast

- Fermenting Beer with Mangrove Jack's M20 Bavarian Wheat Yeast