Fermenting Beer with Wyeast 2042-PC Danish Lager Yeast

Published: December 15, 2025 at 9:41:03 PM UTC

Wyeast 2042-PC Danish Lager Yeast is a liquid lager strain highly valued by homebrewers and craft brewers. It is known for producing clean, well-balanced lagers. This yeast is often listed in lager yeast comparison tables as Danish Lager or Copenhagen lager yeast.

Wyeast describes 2042 Danish Lager as producing a rich, Dortmunder-style profile. It has a crisp, dry finish and a soft character that enhances hop detail. The strain is released quarterly, which means homebrewers need to plan ahead for sourcing.

Key Takeaways

- Wyeast 2042-PC is marketed as a Danish/Copenhagen lager yeast ideal for clean, balanced lagers.

- The strain produces a Dortmunder-like richness with a crisp, dry finish that highlights hops.

- It resembles White Labs WLP850 and has similarities to W34/70 but is distinct.

- Quarterly release scheduling means brewers should plan yeast sourcing in advance.

- This guide focuses on practical fermentation and handling for homebrewers and small craft brewers.

Overview of Wyeast 2042-PC Danish Lager Yeast

Wyeast 2042-PC is a liquid culture designed for brewers seeking a clean, crisp lager. It boasts a soft mouthfeel and a dry finish, perfect for showcasing hop clarity. In pilsners, Dortmunder, and hop-forward lagers, it provides a balanced malt backbone.

The yeast profile highlights neutral ester production and reliable attenuation. It has a steady fermentation pace and excellent flocculation, aiding in post-fermenting clarity. This makes it ideal for traditional lager styles requiring subtle yeast behavior.

Comparisons show Wyeast 2042-PC is close to White Labs WLP850 and similar to W34/70 from Danstar and Fermentis, with slight differences. It's a quarterly release, so availability is limited. Homebrewers should plan their batches around these release windows or find comparable strains when Wyeast 2042-PC is out of stock.

When designing recipes, the Danish lager profile is key. It ensures hop aromas remain vibrant while malt is supportive but not overpowering. Expect a clean fermentation and a dry, Dortmunder-style finish, suitable for a broad range of lager recipes.

Why Choose Wyeast 2042-PC Danish Lager Yeast for Your Lager

Wyeast 2042-PC brings a rich Dortmunder-style body with a crisp, dry finish. It's perfect for brewers aiming for the best lager yeast. Its soft malt framing allows hop character to shine.

This strain excels as a hop-accenting yeast. It supports citrus and noble hops without harsh esters. This makes it ideal for hop-forward lagers and classic European styles that require clarity and balance.

When comparing options, you'll find similarities with White Labs WLP850 and Fermentis' W34/70 family. These alternatives perform well when 2042 is out of season. However, each strain may exhibit slight differences in attenuation and flocculation.

Availability is a key factor. Wyeast 2042 ships quarterly in many markets. Plan your purchases or build starters to achieve the desired cell counts. This planning helps ensure consistent results with clean lager strains.

- Flavor: full mid-palate, dry finish.

- Use case: hop-accenting yeast for pilsners and Dortmunder-style lagers.

- Substitutes: WLP850, W34/70 — monitor subtle differences in behavior.

- Logistics: buy ahead or prepare starters during off-release periods.

For brewers seeking a neutral canvas that highlights malt and hops, Wyeast 2042 is a wise choice. It ranks among the top lager yeast options for a reliable, clean performance that showcases your recipe's intent.

Yeast Biology and Fermentation Basics for Lager Strains

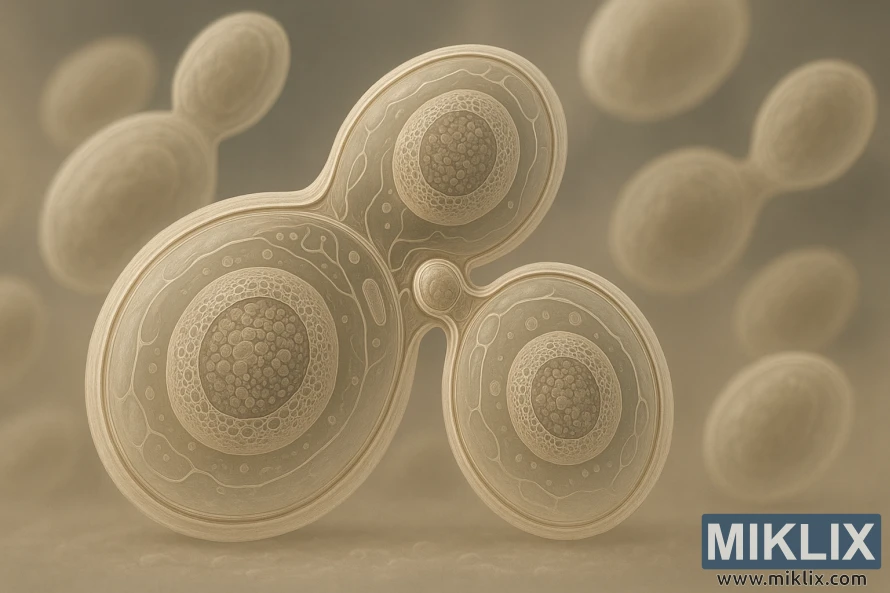

Yeast is the driving force behind brewing, transforming wort sugars into alcohol and carbon dioxide. Grasping lager yeast biology is crucial for brewers to forecast flavor, attenuation, and alcohol tolerance. The choice of yeast significantly influences the beer's aroma and mouthfeel, impacting its style and balance.

Lager yeasts, classified as bottom-fermenting, belong to the Saccharomyces pastorianus species. They ferment at cooler temperatures than ale yeasts, resulting in a cleaner profile with fewer fruity esters. This characteristic is key to traditional lager styles.

Expect slower activity from S. pastorianus compared with ale strains. Fermentation basics for lagers include patience and attention to temperature control. Cooler fermentation slows metabolism, which reduces ester formation and yields a crisper finish.

Many lager strains exhibit strong flocculation, settling towards the end of fermentation. Brewers often plan a diacetyl rest near the finish to let yeast reabsorb off-flavors and polish the beer. This step is essential for achieving the desired clean, soft profile of commercial lagers.

Practical tips for working with bottom-fermenting yeast include proper wort oxygenation and pitching adequate cell counts. Good oxygen and healthy yeast support a steady, predictable fermentation. For craft brewers using Wyeast 2042, these fermentation basics aid in producing a crisp, dry lager with restrained esters.

Preparing and Handling Wyeast 2042-PC Danish Lager Yeast

Wyeast 2042 arrives as a liquid culture. Always check the production and expiration dates before buying. Storing the yeast in the fridge is crucial for maintaining its viability.

Sanitation is key. Ensure all surfaces, hands, and tools are clean and sanitized before opening the yeast pack. Only open the package when you're ready to use it to avoid contamination.

- Inspect the yeast smack pack for swelling or leaks. A firm, intact pack is a good sign.

- If a starter is needed, prepare it in a sanitized flask and watch for visible activity before pitching.

- When time is tight, pitch the yeast directly after a healthy starter shows active fermentation.

Liquid yeast counts can vary by batch and supplier. Brands like Imperial Organic Yeasts might report higher cell counts. If your recipe requires a precise pitching rate, keep an eye on cell counts.

Store unused packs cold and use them promptly. Since liquid packs may be seasonal, plan your purchases around your brewing schedule. Proper storage reduces the need for large starters and ensures consistent lag times.

When working with Wyeast 2042, aim for simplicity and consistency. Mix the starter gently and transfer it to cooled wort quickly to minimize stress. With proper preparation and storage, you enhance the likelihood of a clean, vigorous lager fermentation.

Pitching Rates and Starter Recommendations

Liquid strains like Wyeast 2042 often ship with lower yeast cell counts than dry or concentrated packs. For a 5–6 gallon lager near 1.050, a lager starter is essential. It ensures a higher pitching rate for clean, steady fermentation.

Use a reliable starter calculator to size the starter for your target gravity. Build the lager starter several days before brew day, especially if the strain is sold on a limited schedule. Aim to hit the recommended pitching rate Wyeast 2042 cell target for lagers.

Aerate starter wort thoroughly and keep it at a warm, optimal temperature for growth. Allow vigorous activity, then cold-crash and decant most of the starter wort before transferring yeast to chilled production wort. This practice reduces the risk of off-flavors from old starter wort.

Priming starters for larger batches can save time and ensure consistency. For high-gravity lagers, a two-step starter often produces the needed cell mass without stressing the culture. Monitor flocculation and activity to judge when the yeast has reached peak growth.

- Calculate required yeast cell counts for your gravity and batch size.

- Make a lager starter sized to reach that pitching rate Wyeast 2042 recommends.

- Aerate, allow strong growth, cold-crash, then decant before pitching.

- Use priming starters or step-ups for high-gravity lagers to avoid underpitching.

Following these starter and handling steps reduces lag phase, promotes clean attenuation, and helps Wyeast 2042 express typical lager character. Accurate cell counts and proper pitching practices matter more for lagers than for most ales.

Recommended Fermentation Temperatures and Schedules

Initiate primary fermentation for Wyeast 2042 within the low 40s to low 50s °F. This temperature range accentuates the clean, crisp profile that lager enthusiasts seek. It's crucial to maintain consistent readings using a reliable thermometer or controller.

A typical lager temperature schedule is beneficial for many homebrewers. Start at 48–52°F during primary fermentation until activity slows and gravity stabilizes near its final value. This phase can last from 7 to 14 days, influenced by yeast health and initial gravity.

Implement a diacetyl rest when fermentation slows and gravity approaches its terminal value. Elevate the beer to 60–65°F for 24–48 hours. This allows yeast to reabsorb diacetyl, enhancing flavor. Perform this step before cold conditioning for optimal results.

Following the diacetyl rest, rapidly cool the beer to near-freezing temperatures for cold conditioning. Extended lagering at these cold temperatures refines flavor and enhances clarity. The overall lager fermentation timeline, from pitching to packaging, can vary from weeks to months, depending on the style and desired clarity.

- Primary: 48–52°F until most fermentation is complete (7–14 days)

- Diacetyl rest: 60–65°F for 24–48 hours

- Cold crash and lagering: near 32–40°F for multiple weeks

Instead of adhering to strict calendar days, focus on gravity readings. A steady rise to final gravity and a clean aroma post-diacetyl rest signify yeast completion. Be cautious with temperature adjustments; sudden changes can stress yeast and introduce off-flavors.

Oxygenation, Nutrients, and Wort Preparation

Effective lager wort preparation begins before yeast is added to the fermenter. It's crucial to have clean, well-modified wort with sufficient free amino nitrogen (FAN). Quality malts like Pilsner or Munich are ideal for this. However, adjuncts such as rice or corn may require additional FAN from a reliable yeast nutrient for lagers to prevent slow or dirty fermentations.

Wort aeration is particularly important for lagers due to their cold fermentation process. This process limits yeast metabolism. Therefore, aim for about 8–12 ppm dissolved oxygen in standard-strength lagers. For high-gravity batches, increase the oxygen target and ensure larger starters are used. Adequate oxygenation supports the production of sterols and membranes before yeast growth in anaerobic conditions.

For consistent results, consider these practical methods:

- Pure oxygen dosing with a sintered stone for precise wort aeration.

- Vigorous shaking or splashing for small-batch starters and home setups.

- Larger, well-aerated starters when pitching rates are critical for high-gravity lagers.

Develop a nutrient strategy in three phases. First, assess or estimate FAN from your grist. Next, add yeast nutrient for lagers when using adjuncts or darker, kilned malts. Finally, stagger nutrient additions if fermentation appears strained, such as stalled gravity or off-flavors.

Keep in mind that lager yeast, like Wyeast 2042-PC, thrive with predictable wort chemistry and controlled oxygenation. Tailor your lager wort preparation to achieve your desired attenuation and flavor profile. This approach minimizes risks of under-attenuation, excessive esters, or sulfur compounds associated with stressed yeast.

Managing Fermentation: Signs, Gravity, and Timing

Start monitoring fermentation from the first 12 to 48 hours. Look for krausen buildup, steady CO2 release from the airlock, and a hazy, active wort surface. These signs indicate yeast activity and confirm adequate oxygen and pitch rate.

If fermentation is slow, check the yeast's temperature and consider warming it gently. Underpitching often causes delayed starts. Using a starter or fresh Wyeast pack can prevent prolonged lag phases.

- Track gravity daily with a hydrometer or refractometer.

- Compare readings to expected attenuation for the style.

- Note that Wyeast 2042 tends toward a dry finish, so your final gravity for lagers may sit lower than some ale strains.

Record specific gravity until it holds steady for three readings over 48–72 hours. This plateau signals primary fermentation's end, reducing overconditioning risks during lagering.

Use simple timing benchmarks to plan the schedule. With correct pitching and oxygenation, primary fermentation usually finishes in 7–14 days. Follow this with a short diacetyl rest at slightly warmer temps to allow yeast to clean up off-flavors.

After the rest, drop temperature for extended lagering to improve clarity and flavor stability. Proper fermentation timing keeps esters low, delivering the clean profile expected from a Dortmunder or pilsner.

Keep clear logs of gravity, temperature, and visible activity. Good records improve future batches and help you spot deviations early during fermentation monitoring and beyond.

Common Fermentation Issues and Troubleshooting

Slow or stuck fermentation is a major concern for homebrewers. It often results from underpitching, low wort oxygen, cold temperatures, or depleted nutrients. First, check the temperature and gravity. If yeast stalled early, try warming the fermenter slightly and consider adding a healthy starter.

To fix sluggish batches, add life, not force. If oxygen was missed at pitch, avoid aerating late in fermentation. Pitching a vigorous starter or fresh lager yeast can restart fermentation. Keep interventions minimal to protect flavor and avoid off aromas.

Diacetyl in lager manifests as a buttery note when yeast are stressed or fermentation finishes too quickly. A diacetyl rest at 62–65°F for two to three days allows yeast to reabsorb it. Monitor gravity to ensure primary fermentation is near complete before the rest. This step minimizes the risk of persistent diacetyl in lager.

Sulfur in lager can smell like rotten eggs or struck matches during active fermentation. Many lager strains produce transient sulfur that fades during conditioning. Extended cold conditioning and gentle fining or filtration can reduce sulfur in lager, leading to a cleaner profile.

- If clarity lags, extend lagering time or perform a cold crash.

- Use finings like Irish moss or silica after fermentation to aid drop clear.

- For persistent off-flavors, check mash temperatures, fermentation schedule, and yeast health for recurring issues.

Track original and final gravity closely. Accurate readings help identify stuck fermentation versus expected slow finish. Keep a log of pitch rate, oxygening method, and temperatures. This practice helps narrow causes when future lager fermentation problems arise and improves consistency.

Water Profile, Malt Bill, and Hop Choices for Best Results

Begin with a water profile that's soft to moderately mineralized to highlight Wyeast 2042's characteristics. For pale lagers, increase sulfate levels to enhance hop crispness. When using pilsner malt, make only slight adjustments to the water to preserve the yeast's clean flavor.

For a Dortmunder, start with Pilsner malt as the base. Add 5–15% light Munich or Vienna to enhance body and introduce a subtle bready sweetness. This combination supports a fuller malt beer while allowing the yeast to finish clean and dry.

Choose hops that complement the style. Noble varieties like Saaz and Hallertau are perfect for traditional European lagers, adding floral and spicy notes. For a modern twist, opt for clean American hops like Cascade or Willamette. They bring citrus and herbal flavors without overpowering the yeast.

The timing of hop additions is crucial. Early additions set the bitterness, while late additions preserve the aroma. For hop-forward pilsners, increase the late hop percentage. This highlights the delicate hop character that 2042 enhances.

- Water profile for lagers: aim for calcium levels between 50–100 ppm; adjust sulfates to enhance dryness in hoppy styles.

- Dortmunder malt bill: combine Pilsner malt with a small amount of Munich for added richness and balance.

- Hops for Danish lager: prefer noble hops for a traditional taste, or clean American varieties for a brighter profile.

- Brewing water adjustments: use gypsum or calcium chloride sparingly to fine-tune the sulfate-to-chloride ratio.

Always taste and adjust. Small tweaks to water profile and malt percentages can have a bigger impact than large yeast changes. Keep detailed records to refine brewing water adjustments and hop choices with each batch.

Comparing Wyeast 2042-PC to Similar Strains and Substitutes

Wyeast 2042-PC is celebrated for its clean lager character and consistent attenuation. Brewers often turn to White Labs WLP850 as a reliable substitute. This is because WLP850 is frequently regarded as the closest lab equivalent to Wyeast 2042.

Lab-to-lab variation is significant. Even with the same strain name, differences in ester profile, attenuation, and flocculation can occur. It's important to view Wyeast alternatives as viable matches, but not exact duplicates.

Danstar and Fermentis offer strains that excel in lagers. Many brewers consider Danstar/Fermentis W34/70 a reliable substitute for WLP850 or Wyeast 2042 when these are not available.

- Primary alternative: White Labs WLP850 for its similar fermentation traits and flavor neutrality.

- Secondary option: W34/70 substitute from Danstar/Fermentis for robust attenuation and cold tolerance.

- General note: lager yeast substitutes will shift results slightly; adjust pitch rate and temp control accordingly.

When choosing lager yeast substitutes, anticipate minor variations in diacetyl rest timing and final gravity. Expect slight changes in mouthfeel and ester expression.

Practical steps for swapping strains:

- Match cell counts and oxygenation rather than relying on pack size alone.

- Adjust fermentation temperature to the chosen strain’s sweet spot.

- Monitor FG and flavor, then fine-tune for future batches.

Wyeast alternatives provide brewers with options when 2042 is out of stock. Use WLP850 as the first choice and keep W34/70 substitute as a dependable fallback.

Conditioning, Lagering, and Clarification Techniques

Start conditioning with a controlled diacetyl rest when primary fermentation is almost done. Increase the temperature to the high 50s–mid 60s°F for 24–48 hours. This allows yeast to reabsorb diacetyl, preventing buttery off-flavors and ensuring a clean finish.

Once the diacetyl rest is over, gradually lower the temperature for cold conditioning. Decrease it by a few degrees each day until you reach near-freezing lagering temperatures. Lagering techniques typically involve holding beers at 32–38°F for a long time. This helps develop clarity and mellow flavors.

The duration of cold conditioning depends on the beer's style and gravity. Light lagers may clear and mature in 2–4 weeks. Munich-style and doppelbocks, however, often require 6–12 weeks or more. Longer periods at low temperature reduce sulfur and ester compounds, polishing the beer's profile.

Clarification techniques can speed up visual clarity and stability in lagers. Cold crashing, extended lagering, and finings like Irish moss at the end of the boil or gelatin in secondary are effective. Some yeast strains are highly flocculent and clear faster, while others need these interventions for a bright appearance.

When lagering, follow basic handling steps: keep the fermenter sealed to limit oxygen pick-up, rack carefully if packaging early, and monitor gravity to confirm stability. Proper sanitation and gentle transfers protect the crisp character achieved by cold conditioning.

Finally, taste periodically and be patient. Flavor rounding and brightness develop slowly during extended cold conditioning. Allow enough time for the beer to reach its optimum clarity and balance before packaging or kegging.

Packaging and Carbonation Recommendations for Lagers

Decide on a packaging method that aligns with your timeline and preferences. Kegging with force carbonation ensures consistent lager carbonation levels and a crisp finish. Homebrewers using Cornelius kegs can precisely control CO2 levels and chill the beer to enhance CO2 absorption.

Bottle conditioning lager is still a cherished choice for those who value tradition and cellaring. Ensure enough active yeast by avoiding extreme cold conditioning. When priming, accurately calculate sugar to achieve your desired carbonation range.

- Typical targets: 2.2–2.8 volumes of CO2 depending on style.

- Pilsners and Dortmunder lagers often sit around 2.4–2.6 volumes.

- Lower carbonation suits Munich-style lagers and some amber lagers.

Sanitation before packaging is crucial. Sanitize bottles, kegs, and transfer lines to ensure shelf stability. A clean fill and minimal oxygen pickup help prevent off-flavors during storage.

If you opt for bottle conditioning lager, monitor temperatures during carbonation. Maintain a consistent warm range for yeast activity, then move to cold storage once the target level is achieved. Avoid over-priming and extended cold lagering to prevent overcarbonation or flat beer.

Force carbonation offers a more controlled and quicker approach. Use a carbonation chart to match pressure and temperature for the desired lager carbonation levels. This method ensures consistent results across batches, reducing wait times.

Keep a detailed record of your process. Note down priming amounts, keg pressure, conditioning time, and measured carbonation. Such records help in replicating successes and refining targets for future lagers.

Recipe Examples and Brewing Notes for Wyeast 2042-PC Danish Lager Yeast

Wyeast 2042 is perfect for brewing Dortmunder Export, Pilsner, and other clean lagers. It offers a crisp, dry finish with a bright hop character. Use Pilsner or Pilsner with a small Munich adjunct as base malts. This combination adds a gentle malt body without overpowering the hops.

Below is a concise outline for a 5-gallon batch of Dortmunder. Adjust water and salt to achieve a soft to moderately hard profile. This will enhance the noble hops' flavor.

- 9–10 lb Pilsner malt

- 1–1.5 lb Vienna or light Munich

- Mash 150–152°F for moderate attenuation

- IBU 18–25 using Saaz or Hallertau

- OG targeting 1.048–1.056

When preparing the yeast, pay close attention to packing and pitching. For higher gravities, ensure your starter is large enough to meet the yeast's pitching needs. Build a starter that matches the target OG and cool the fermentation volume to avoid underpitching.

Ferment at temperatures between 48–52°F. Allow a diacetyl rest near 60–62°F for 24–48 hours before cold conditioning. Lager for 4–8 weeks to achieve clarity and smooth flavors.

Adapting other Danish lager recipe styles? For a Czech Pilsner, reduce Munich and emphasize Saaz. For a clean American lager, use clean American hops and keep the malt simple.

Follow these best practices: oxygenate the wort well before pitching, plan a starter for every liquid Wyeast 2042 pack, and have substitutes like White Labs WLP850 or W34/70 if 2042 is out of stock. Keep clear pitching notes in your brew log to replicate success.

Conclusion

Wyeast 2042-PC Danish Lager Yeast is a valuable asset for homebrewers aiming to craft clean, Dortmunder-style lagers. Its soft malt profile and crisp dry finish make it ideal for showcasing hop character. Fermented cool and clean, it stands out among other strains, similar to White Labs WLP850 and Danstar W34/70.

To maximize its potential, plan ahead. This yeast is a quarterly release, so securing packages early is crucial. Building a starter is essential to meet proper pitching rates. Low-temperature fermentation, a diacetyl rest, and extended cold conditioning are key to achieving the clarity and balance of classic lagers.

This review underscores Wyeast 2042's effectiveness for U.S. homebrewers seeking hop-accented, clean lagers. Proper oxygenation, nutrients, and temperature control are vital. They ensure predictable attenuation and a polished finish, enhancing both traditional and modern lager recipes.

Further Reading

If you enjoyed this post, you may also like these suggestions:

- Fermenting Beer with Lallemand LalBrew Windsor Yeast

- Fermenting Beer with Wyeast 1098 British Ale Yeast

- Fermenting Beer with CellarScience Saison Yeast