Hops in Beer Brewing: Janus

Published: November 11, 2025 at 9:24:08 PM UTC

Hops are crucial in beer brewing, influencing flavor, aroma, and bitterness. The Janus hop variety is notable for its dual role as both a bittering and aroma hop. It is listed in the Oregon State University High Alpha Acid Breeding Program inventory, signifying its importance in hop germplasm collections.

This article explores Janus hops' unique potential for creating distinctive beer flavors. Using Janus in brewing can impact the balance of alpha and beta acids, essential oil composition, and the final aroma. We will delve into its history, chemical makeup, agronomy, processing, storage, recipe development, and direct brewing applications.

Key Takeaways

- Janus hops occupy a clear place among hops in beer brewing as a versatile variety.

- The Janus hop variety is cataloged in major breeding program inventories, reflecting its research relevance.

- Brewing with Janus affects bitterness and aroma due to its alpha/beta acids and essential oils.

- Later sections will detail agronomy, storage, and recipe tips to maximize Janus performance.

- Readers will get practical comparisons to popular hop varieties and real-world examples.

Overview of Hops in Beer Brewing

Hops play a crucial role in beer, serving three main functions. They introduce bitterness by releasing alpha acids during boiling. Additionally, they add flavor and aroma through essential oils, especially when added late or used for dry hopping. Lastly, hops act as antimicrobial agents and stabilizers, protecting the beer's quality.

Brewers categorize hops to make recipe decisions easier. Bittering hops, with their high alpha-acid content, are added early to achieve the desired bitterness. Aroma hops, rich in essential oils, are added later to enhance the beer's scent. Dual-use hops offer a balance, suitable for both bittering and adding aroma.

- Hop functions: control bitterness, contribute flavor and aroma, and aid beer stability.

- Bittering hops: chosen for predictable alpha-acid content and clean bitterness.

- Aroma hops: prized for citrus, floral, spice, or resinous notes when added late.

- Dual-use hops: flexible for brewers who want one variety to serve multiple purposes.

Effective brewing depends on aligning hop functions with the beer's style and goals. American IPAs often use high-alpha bittering hops with multiple dry-hop additions for aroma. Belgian ales, on the other hand, might employ lower-alpha aroma hops to avoid harsh bitterness and highlight delicate oils. Understanding these categories helps brewers set alpha-acid targets, plan IBU contributions, and select finishing hops for the desired aroma.

This overview sets the stage for Janus within these classifications. It prepares readers for a deeper exploration of its composition and application in subsequent sections.

History and Breeding of Hop Varieties

Modern hop varieties have evolved over centuries, thanks to meticulous hop selection and targeted breeding. Early cultivars like Fuggle and Brewer’s Gold laid the groundwork. Breeders then expanded these genetic foundations through crosses and seedling selection.

Techniques such as open pollination, controlled crosses, and chromosome doubling were employed. These methods are documented in USDA and Oregon State University hops records. They detail the parentage and pedigrees of various hop varieties.

Records from the USDA/OSU hop germplasm collection highlight the influence of Brewer’s Gold on high-alpha lines. Fuggle, and its tetraploid derivative, led to the creation of triploid offspring like Columbia and Willamette. These were developed through controlled crosses, such as cross 6761.

Breeding objectives have evolved over time. Initially, the focus was on increasing alpha acids for bittering. Later, breeders aimed for better aroma profiles and enhanced storage stability. Disease resistance to downy mildew and verticillium became crucial for reliable yields and quality.

The Oregon State University hops program and USDA inventories have been pivotal in preserving hop diversity. Their collections have supported hop selection for desirable traits like seedlessness. These traits are highly valued by growers and brewers.

Janus is a product of this extensive breeding history. Its characteristics reflect the decades of work documented in public germplasm repositories and breeding program notes.

Janus hops

Janus is listed in the Oregon State University inventory as part of a High Alpha Acid Breeding Program. It is noted in the Janus OSU listing among many US and international cultivars. This indicates its formal inclusion in public germplasm records.

Currently, available notes do not provide full chemotype values. For a comprehensive Janus hops profile, brewers and growers should refer to OSU extension materials, USDA GRIN entries, or hop merchant technical sheets. These sources offer alpha acids, beta acids, oil content, and cohumulone figures.

The breeding program context suggests Janus was developed with high alpha acid goals or for dual-purpose use. This aligns with the typical objectives of high-alpha programs. They aim to provide reliable bittering potential while retaining aroma utility.

Janus hop characteristics are partially undocumented in public excerpts. Interested parties should verify current agronomic traits such as yield, disease resistance, and storage stability. This is crucial before ordering seedstock or designing recipes.

- Check the Janus OSU listing for accession identifiers and breeding notes.

- Request lab or merchant data for an up-to-date Janus hops profile.

- Confirm Janus hop characteristics like oil profile and alpha percentages prior to commercial use.

Brewers planning to use Janus should view available records as a starting point. Confirmed analytical data is essential for formulation and agronomy decisions.

Alpha and Beta Acids: What Brewers Need to Know

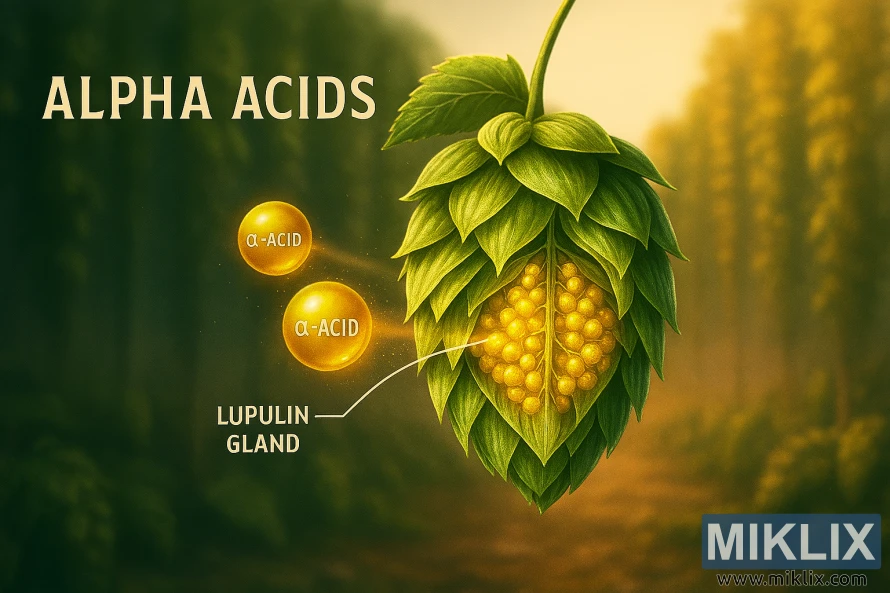

Alpha acids are the backbone of a hop's bittering power. Brewers use them to calculate IBUs, taking into account boil time, wort gravity, and utilization rates. High-alpha varieties are ideal for concentrated bittering, allowing for fewer hops to achieve the desired IBU.

Beta acids, on the other hand, play a unique role. They don't isomerize well during boiling but contribute to bitterness over time. Oxidation products from beta acids can introduce harsh notes if hops degrade, yet they also offer antimicrobial benefits.

Cohumulone, a subset of alpha acids, significantly influences bitterness. A higher cohumulone percentage can result in a sharper, more astringent bitterness. Modern breeding focuses on balancing cohumulone to achieve smoother bitterness profiles.

- Brewer’s Gold: alpha acids ~9.2% (range 7.1–11.3%), beta ~4.8% (3.3–6.1%), cohumulone ~39%.

- Fuggle: alpha ~5.1%, cohumulone ~27%.

- Willamette: alpha ~6.6%, cohumulone ~29–35%.

Storage stability is crucial for hop bittering chemistry and final IBUs. Older hops like Brewer’s Gold may lose alpha-acid potency faster than newer varieties. Proper storage ensures alpha acids and beta acids remain stable, maintaining consistent IBUs.

To manage bitterness, measure alpha acids on hop certificates and adjust accordingly. Tracking cohumulone helps assess harshness risk. Understanding hop chemistry is key to achieving the desired IBUs and shaping the beer's final taste.

Essential Oils and Aroma Profiles

Hop essential oils are key to the hop aroma brewers aim for. They add hops late in the boil, during the whirlpool, or as dry hops. These oils, measured as percentages or ml/100 g, define the beer's scent and taste.

Myrcene contributes resinous, citrusy, and tropical notes. Humulene brings herbal or woody flavors. Caryophyllene adds spicy, peppery notes. Minor oils like farnesene enhance the floral aspects, completing the aroma.

OSU and USDA data reveal significant variation in oil percentages across hop varieties. For instance, Brewer’s Gold has about 1.96 ml/100 g total oil. Myrcene dominates at roughly 66.7%, humulene near 11.3%, and caryophyllene about 6.5%. Fuggle, on the other hand, has lower oil content, with myrcene at 43.4%, humulene 26.6%, and caryophyllene 9.1%.

Willamette falls between these ranges, with total oil around 0.8–1.2 ml/100 g. Myrcene is near 51%, humulene about 21.2%, and caryophyllene close to 7.4%. Classic noble hops like Hallertauer Mittelfrüh have a higher humulene share, creating a delicate, spicy-hop aroma.

Brewers use the humulene-to-myrcene or humulene-to-caryophyllene ratio to predict hop character. A higher humulene ratio suggests subtle, herbal notes. Dominant myrcene yields bright citrus and tropical characters.

Practical brewing choices hinge on the hop's oil profile. Always check the Janus technical sheet for hop essential oils and oil percentages before planning additions. Late-boil and dry-hop additions preserve volatile oils like myrcene, humulene, and caryophyllene. This allows brewers to fine-tune citrus, pine, floral, or spicy notes with precision.

Brewing Applications for Janus hops

Janus hops can serve as a bittering variety or as a dual-use hop in a brewer's arsenal. Before deciding, check the supplier's alpha-acid numbers and oil profiles. This will help determine whether to use Janus for early boil additions or for later flavoring.

If the alpha-acid level is high, plan for early additions to efficiently reach your target IBUs. Use standard IBU calculators, adjusting for wort gravity and boil time. This will ensure predictable Janus bittering results.

When oil breakdown shows significant myrcene and humulene, consider adding some hops 15 minutes or later, or for dry-hopping. These placements will enhance the Janus aroma, bringing out citrus, resinous, or herbal notes.

For a moderate alpha and balanced oils, treat Janus as a true dual-use hop. Split additions across the boil, whirlpool, and dry-hop. This approach will create a layered profile that supports both bittering and aroma.

- Supplier checks: confirm alpha-acid percentage and oil composition before scaling recipes.

- IBU planning: calculate additions based on measured alpha to hit bitterness targets.

- Timing: early for Janus bittering; late or dry-hop for Janus aroma.

Pairing choices significantly impact how Janus hop uses are perceived in the finished beer. Clean American ale yeasts and neutral pale malts allow hop character to shine in IPAs and American pales. For malt-forward beers, add Janus sparingly late to enhance with resinous or citrus accents.

Pilot batches are crucial. Small-scale trials help fine-tune rates and schedules to local equipment and water. Track perceived intensity across trials to refine Janus deployment in future brews.

Comparisons with Popular Hop Varieties

This hop comparison examines Janus against benchmark cultivars to help brewers choose replacements or complements. Janus vs Cascade highlights differences in aroma: Cascade brings citrus and grapefruit, while Janus leans toward sharper bittering and resinous notes when used at high rates.

Look at oil and acid figures for context. Brewer’s Gold has an alpha around 9.2% with myrcene at roughly 66.7%, offering strong resinous, citrus character. Willamette reports alpha near 6.6% with myrcene near 51% and humulene about 21.2%, giving a floral, English aroma. Fuggle sits lower, alpha about 5.1% and humulene near 26.6%, lending classic earthy tones.

Compare practical uses. If Janus matches Brewer’s Gold on alpha acids, it performs well as a bittering hop and can replace super-alpha varieties. In a different scenario, Janus vs Willamette matters when aroma balance counts; a Janus with Willamette-like oil ratios could serve as an English-style aroma hop.

Brewers should weigh storage and cone traits before swapping hops. Historic Brewer’s Gold had weaker storage stability than Cluster selections, and modern breeding focused on improving shelf life. Ask whether Janus keeps alpha and oil levels over months like Cluster or degrades faster.

- Alpha comparison: use measured alpha to decide bittering roles.

- Aroma fit: match myrcene, humulene and caryophyllene profiles to recipe goals.

- Storage and yield: consider cone integrity and stability versus old standards like Brewer’s Gold and Cluster.

Small-scale trials remain the best test. Brew a single-batch swap to compare Janus vs Cascade or Janus vs Willamette in real wort. Tasting side-by-side reveals how hop comparison numbers translate into aroma, bitterness, and mouthfeel.

Growing and Agronomy Considerations

Successful hop agronomy begins with selecting the right site and understanding cultivar traits. Growers must review USDA and Oregon State University accession notes. These notes detail maturity timing, vigor, and hop disease resistance before planting.

Soil health and rotation are crucial for long-term yield. Soil pH and organic matter levels should be tested. Then, plan cover crops and rotations to combat verticillium and other soilborne issues. Good drainage is essential to reduce root stress and enhance pickability.

Janus cultivation demands specific checks. Confirm the cultivar's ploidy and propagation method with suppliers. Using certified virus-free plants or clean rhizomes minimizes early losses and ensures consistent yield.

Managing sidearm length is vital for matching trellis and harvest systems. The typical range in common cultivars shows how architecture impacts labor needs and yield. Adjust training practices to keep sidearm length within desired limits for mechanical or hand harvest.

Monitoring disease pressure through scouting and records is essential. Some classic varieties, like Fuggle, exhibit strong downy mildew resistance. However, responses vary by cultivar. Obtain hop disease resistance profiles for Janus from OSU or seedstock sources and plan integrated pest management accordingly.

Breeders use ploidy shifts to enhance traits. Triploids and tetraploids may offer seedlessness and different vigor. Confirm whether Janus is available as a clone or polyploid to set expectations for propagation and field performance.

Record yields in pounds per acre and compare against regional benchmarks. Brewer’s Gold and Willamette often produce in the mid-thousands of pounds per acre. Older landraces like Fuggle sit lower. Use supplier and extension data to estimate Janus yield and economic viability.

Plan harvest timing around maturity windows. Early or late maturity impacts hop processing and alpha acid stability. Coordinate harvest crews, drying capacity, and storage to protect oil profiles and maintain market value.

Keep notes on vigor, leaf color, and storage stability as the planting matures. These agronomic observations help refine site choice and cultural inputs for future plantings. They support steady improvement in Janus cultivation.

Processing and Storage Impact on Hop Performance

Hop processing significantly influences their performance in brewing. Whole-cone hops tend to break and shed lupulin during handling. In contrast, pellet forms compress lupulin into a denser mass, better resisting oxygen and light. Brewers must carefully consider pellet vs whole cone when planning hopping rates and dry-hop management.

Alpha acid retention is influenced by both processing and storage. Studies from USDA and Oregon State University reveal cultivar differences in hop degradation under room conditions. For instance, some Cluster selections retained 80–85% of their alpha acids after six months. Meanwhile, Fuggle retained about 75%. Brewer’s Gold has historically shown poor hop storage stability in similar trials.

Cold, oxygen-free storage is crucial for preserving volatile oils and alpha acids. Vacuum-sealed packaging, kept refrigerated or frozen, slows hop degradation and supports consistent IBUs. It's essential to verify each batch with a supplier certificate of analysis to confirm current alpha acid and oil levels before adjusting recipes.

The choice between pellet and whole cone impacts utilization and trub. Pellets often enhance consistency and shelf life but produce more compact hop matter at the end of a dry-hop. This can affect filtration and clarity steps. Whole cones may yield a cleaner break in some beers but require faster handling to limit loss of aromatics.

- Best practice: store hops cold and keep oxygen out to maximize hop storage stability.

- Check COAs for up-to-date alpha acid retention figures when scaling recipes.

- Expect some hop degradation over time and adjust hopping rates accordingly.

Recipe Development Tips Using Janus hops

Begin by securing a current Certificate of Analysis for Janus. This confirms the alpha-acid percentage and essential oil composition. Use this information to calculate IBUs and design a hopping schedule that aligns with your desired bitterness and aroma.

If the COA indicates Janus is high-alpha, treat it as a base bittering hop. Add it to the boil for 60–90 minutes. Adjust the utilization based on whether it's in pellet or whole-cone form. Then, plan for late-boil or whirlpool additions with a complementary aroma hop to enhance the finish.

When Janus is noted as dual-use or aroma-forward, focus on whirlpool and dry hop treatments. These methods capture volatile oils effectively. Dry-hop ranges typically span from 0.5 to 3.0 oz per gallon, depending on brewery size and desired intensity.

- Hopping schedule tip: stagger whirlpool and dry-hop timing to protect citrus and herbal notes.

- Adjust dry-hop weight and contact time in pilot runs to avoid vegetal or rubbery off-notes.

For balancing malt and hops, consider style and pairing guidance. In American pale ales and IPAs, use neutral ale yeasts like Wyeast 1056, White Labs WLP001, or US-05. Pair these with pale malts to highlight Janus's character. For English ales, blend Janus with lower-alpha English aroma hops like Fuggle or Willamette, and add more malt backbone.

Run small pilot batches to fine-tune sensory targets. Single-step trials that vary late-addition weights and dry-hop durations help refine citrus, pine, or herbal impressions. This is based on the oil profile measured from the COA.

- Calculate IBUs from the COA and choose an initial hopping schedule.

- Decide whether Janus will be a bittering base or an aroma partner.

- Test 0.5–3.0 oz/gal for Janus dry hop and scale for production.

- Cold-condition and carbonate before final sensory evaluation.

Keep detailed notes during trials to refine settings for carbonation, contact time, and dry-hop intensity. This iterative approach ensures consistent results and improves balancing malt and hops in future Janus hop recipes.

Case Studies and Examples

Small regional brewers like Trouble Brewing, White Gypsy, O Brother, and Galway Bay pubs offer valuable insights. Their tasting notes reveal the impact of late additions and dry hopping in pale ales. These notes highlight bright lemon zest and piney flavors.

Low-ABV pale ales teach a crucial lesson. Brewers find that hops like Vic Secret and Summer, when used fresh, deliver a clean, zippy hop impact. This sharp citrus and pine resin profile serves as a guide for using Janus hops effectively.

The choice of malt and serving temperature significantly influence how hops are perceived. Lighter malts and warmer temperatures enhance hop aroma and intensity. Conversely, cold temperatures and heavy malts can obscure these flavors, making beers taste thin.

- Document ABV, hopping schedule, malt bill, yeast strain, and storage conditions during trials.

- Use fresh, well-stored hops to keep flavor bright and clean.

- Prioritize late additions and targeted dry-hop regimes for sharp citrus and pine notes.

These examples from hop-driven beers and brewery practices outline a practical approach for Janus trials. By tracking sensory changes across batches, brewers can identify Janus-specific traits. This allows for refining recipes for commercial release.

Conclusion

Janus hops summary: evaluating this OSU/USDA-recorded variety against its current specs is crucial for brewers and growers. Alpha and beta acids, cohumulone levels, essential oil profile, storage stability, and agronomic traits all influence its performance in the kettle and field. Before widespread use, obtain up-to-date certificates of analysis from Oregon State University, USDA GRIN, or reputable hop suppliers.

Hop selection summary: grasping bittering, aroma, and dual-use roles is key to recipe strategy. The biochemical drivers — acids for bitterness and oils for aroma — interact with malt, yeast, and processing choices. Testing Janus in small pilot brews reveals its sensory footprint, aiding in refining hopping schedules for desired outcomes.

Janus brewing potential: practical next steps include acquiring fresh COAs, running controlled pilot batches, and conducting agronomic trials to assess yield and disease resistance. Follow best practices for drying and cold storage to preserve hop performance. With accurate technical data and systematic testing, Janus can be used effectively as a bittering, aroma, or dual-use hop to craft distinctive and balanced beers.

Further Reading

If you enjoyed this post, you may also like these suggestions: