Fermenting Beer with Lallemand LalBrew Wit Yeast

Published: October 12, 2025 at 8:47:36 AM UTC

Lallemand LalBrew Wit Yeast is a dry wheat beer yeast, crafted for Belgian-style witbier and wheat-forward ales. It's part of Lallemand’s LalBrew line, available through retailers and distributors across the world.

This review aims to address practical brewing concerns for home and small commercial brewers. It covers fermenting witbier with LalBrew Wit, expected fermentation performance, flavor impact, and handling tips. It also includes troubleshooting common issues and proper storage. Lallemand supports new brewers with technical resources and satisfaction guarantees, aiding in the decision to choose LalBrew Wit for a recipe or when buying online.

Key Takeaways

- Lallemand LalBrew Wit Yeast is designed for wheat beers and witbier fermentation.

- Available through Lallemand distributors and retail partners; product pages show customer reviews and common shipping deals.

- The article will cover fermentation performance, flavor, handling, troubleshooting, and storage.

- Lallemand offers technical support and satisfaction assurances useful to brewers in the U.S.

- This review targets practical, recipe-focused advice for home and small commercial brewers.

Why Choose Lallemand LalBrew Wit Yeast for Your Witbier

Homebrewers choose LalBrew Wit for its dependable profile, ideal for a variety of wheat-forward styles. Its lower ester and phenol output stands out, compared to traditional hefeweizen strains. This makes it a top pick for those looking to create a balanced Witbier.

The yeast provides a subtle banana-and-spice base, allowing for the addition of coriander, orange peel, and other spices. This flexibility makes it perfect for both traditional and modern recipes. It's a strong contender for the best yeast for witbier.

LalBrew Wit offers consistent attenuation and predictable fermentation. It works well with both modern and traditional mash bills. This yeast is suitable for a range of styles, including Belgian Witbier, American Wheat, and Hefeweizen.

Being part of Lallemand’s LalBrew core strains, this yeast is available through recognized partners like White Labs. This wider distribution ensures brewers can access it for both small and large batches. It's a key factor for those planning seasonal or scaled-up brews.

When selecting a wheat beer strain, consider the balance between character and neutrality. LalBrew Wit excels in recipe design and adjunct showcase. It's a brewer-friendly choice for those who value control over flavor layers.

Understanding Fermentation Profile and Performance

LalBrew Wit offers a controlled fermentation profile LalBrew Wit brewers can rely on for a clean wheat base. The yeast performance is consistent, efficiently consuming sugars and keeping ester and phenol levels in check. This is unlike classic hefeweizen strains.

Attenuation ranges from 75% to 82%, ensuring a dry finish without over-attenuation. This range supports medium-strength beers, allowing for adjustments in mash to shape the beer's body and mouthfeel.

The yeast's alcohol tolerance is medium-to-high, around 8–12% ABV. This flexibility allows brewers to create stronger wheat beers while maintaining balanced flavors and controlled esters.

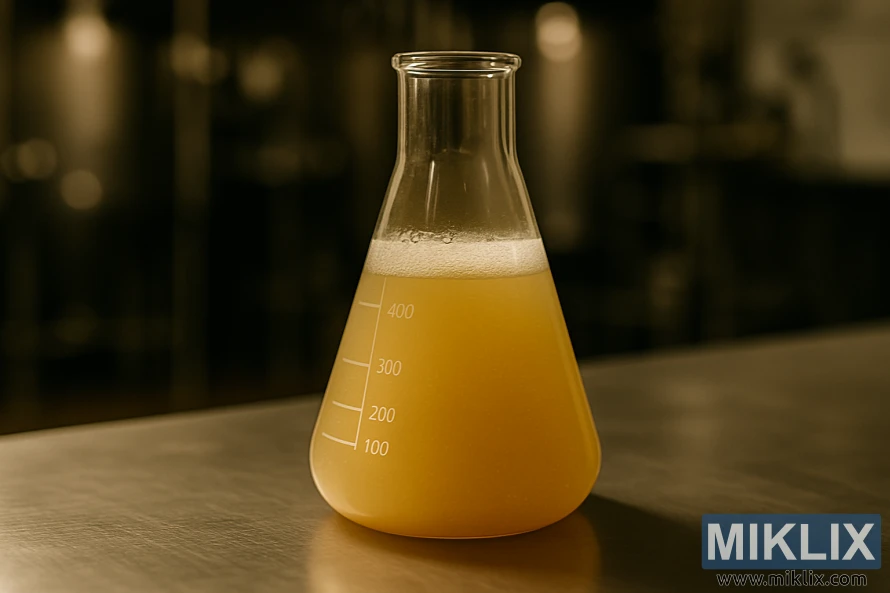

Flocculation is low, leading to slow settling. This means conditioning time needs careful planning. The low flocculation also affects clarity, requiring filtration or extended cold conditioning to achieve the desired brightness.

- Fermentation profile LalBrew Wit: neutral backbone with light banana and spice aromatics.

- Yeast performance: efficient sugar uptake and reliable attenuation range.

- LalBrew Wit characteristics: medium-to-high alcohol tolerance and low flocculation.

- Yeast behavior: slow settling that impacts conditioning and clarification timelines.

Grasping these metrics is crucial for recipe design and fermentation planning. Adjustments in pitch rate, temperature control, and conditioning time are necessary to align with the LalBrew Wit characteristics desired in the final beer.

Recommended Fermentation Temperatures and Ranges

Lallemand suggests fermenting LalBrew Wit between 63-77°F. This range allows brewers to control ester and spice levels while ensuring yeast health.

At the cooler end, around the mid-60s, the fermentation temperature results in a cleaner beer. This profile is characterized by fewer esters and less clove. Brewers aiming for a crisp finish often target this temperature range.

On the warmer side, near the mid-70s, the yeast produces more pronounced banana and spice notes. Choosing the warmer end of the range can enhance traditional witbier aromas for those preferring a more yeast-forward beer.

Exceeding the recommended temperature range can lead to issues. One brewer pitched at about 80°F, resulting in sharp, stressed flavors and prolonged cleanup. Proper temperature control is crucial to avoid stressed yeast and off-flavors.

- Cool the wort to within the fermentation range 63-77°F before pitching when possible.

- Time rehydration and pitching to minimize warm-wort stress on LalBrew Wit fermentation temperature.

- Use a temperature-controlled chamber or swamp cooler for steady temperature management during active fermentation.

The ideal temperature for brewing witbier depends on the desired flavor profile. Use the fermentation range 63-77°F as a starting point. Adjust within this range to find the perfect balance between a clean and expressive yeast character.

Rehydration and Pitching Best Practices

Adhere to Lallemand’s rehydration guidelines for LalBrew Wit to maximize its potential. Use sterile, oxygen-free water at the specified temperature. Gently stir and wait the recommended time before adding the yeast to the wort.

When pitching dry yeast, accurately measure the rate, crucial for wheat-forward beers. LalBrew Wit requires a sufficient cell count due to the high protein and suspended solids in wheat beers. Ensure the cooled wort is well-oxygenated before adding dry yeast for a vigorous start.

Delays in wort cooling after rehydration can still allow pitching, but risks exist. Yeast stressed by warm wort may settle slower and produce off-flavors. A homebrewer shared their experience pitching into warmer-than-ideal wort when no other option was available.

- Ensure the rehydration water is clean and at Lallemand’s recommended temperature.

- Align pitching timing with wort temperature to prevent thermal shock.

- Provide adequate oxygen to the wort before pitching LalBrew Wit for optimal fermentation.

Prepare in advance to pitch LalBrew Wit effectively. Sanitize equipment, plan for wort cooling, and determine the necessary cells or sachets. Adhering to yeast handling best practices minimizes risks and enhances fermentation predictability.

For direct pitching without rehydration, evenly sprinkle dry yeast over the wort surface. This method can be used in emergencies but results in lower initial viability compared to proper rehydration. Assess the trade-offs and select the method that aligns with your schedule and equipment.

Monitor fermentation closely. Rapid, consistent activity signals successful pitching and proper yeast handling. If fermentation is slow, check the temperature, oxygen levels, and the adequacy of the pitch rate for the beer’s gravity and wheat content.

Managing High or Over-Temperature Fermentations

When LalBrew Wit ferments too hot, it can alter the beer's flavor profile. Starting the fermentation at 80°F or letting it get too warm can lead to increased ester and phenol production. This raises the risk of off-flavors that taste like solvents. Yeast stress is also more common if the yeast wasn't pitched at the right rate.

To tackle hot fermentation, cool the fermenter as quickly as possible. Move it to a cooler room or use a swamp cooler with ice. An immersion chiller on recirculating wort before pitching can also help prevent issues.

Keep a close eye on gravity and aromas during the recovery phase. If the gravity stalls or you notice harsh solvent notes, it's a sign of severe yeast stress. If fermentation continues, consider a diacetyl rest to remove buttery off-flavors. But, avoid keeping the beer too warm, as LalBrew Wit can only tolerate temperatures up to about 77°F.

For future batches, adjust your pitching and aeration techniques to reduce yeast stress. Proper rehydration, healthy oxygenation, and the correct pitch rate are key. LalBrew Wit can handle warmer temperatures, but going beyond 77°F can change the beer's character.

- Quick cooling: move fermenter or use swamp cooler

- Assess yeast health: check krausen, gravity, and smell

- Hold diacetyl rest only if needed and monitor closely

- Improve rehydration, oxygenation, and pitch rate next time

Flavor Contributions and How to Shape Them

LalBrew Wit presents a soft base of banana and gentle spice aromas. It has lower ester and phenol intensity than traditional hefeweizen strains. This makes it an excellent choice for creating a balanced witbier.

To enhance yeast character, control fermentation temperature. Fermenting at the cooler end of the recommended range results in a cleaner beer. It showcases subtle yeast esters and phenols. Warmer fermentation, on the other hand, brings out fruit and spice, adding complexity.

Adjust the grain and adjunct bill to support the yeast notes without masking them. A lighter malt backbone allows the LalBrew Wit flavor to shine. It keeps the body and mouthfeel fitting for a witbier.

- Use coriander and bitter orange peel to complement yeast spice without overpowering it.

- Add spices in the whirlpool for integrated aroma and flavor.

- For brighter, sharper spice aromatics, add spicing witbier ingredients late or post-fermentation.

When shaping witbier flavor, treat spicing as a partner to the yeast. Measure and taste in small test batches. Let the yeast esters and phenols provide subtle complexity. Then, layer coriander or orange to achieve a rounded final beer.

Mash and Wort Considerations for Wheat-Forward Beers

To achieve the distinctive chewy body and natural haze of wheat-forward wort, create a grain bill with a significant wheat malt percentage. For American Wheat or Weizenbock, aim for 40–70% wheat. For Berliner Weisse or Gose, reduce wheat and increase pale malt and adjuncts to enhance tart or saline flavors.

When mashing for LalBrew Wit, maintain a flexible mash thickness. Thicker mashes contribute more body and dextrins, while thinner mashes enhance fermentability. Adjust the mash thickness according to the style and the yeast's attenuation expectations.

Utilizing raw wheat or flaked wheat necessitates a short protein rest. A 15–20 minute protein rest at 122–131°F aids in breaking down large proteins and simplifies lautering. This protein rest also improves head retention and minimizes the risk of a stuck mash.

Focus on the choice of lautering aids and grind. A slightly coarser crush and the addition of rice hulls can enhance run-off when brewing with a high wheat content. These measures are crucial for maintaining consistent extraction in a wheat beer mash plan.

Ensure thorough oxygenation of the wort before pitching. Top-fermenting ale yeasts, such as LalBrew Wit, benefit from adequate oxygen levels to foster healthy cell growth and reach desired attenuation. Proper oxygenation complements mash decisions, leading to a balanced final product.

Adjust adjuncts and mash profile to align with style goals. For tart styles, slightly lower the mash temperature to encourage fermentability. For fuller wheat-forward wort beers, increase the mash temperature towards 154–156°F for enhanced body. Taste and gravity targets should guide these adjustments.

- Target mash temps by style: 150–152°F for lighter body, 154–156°F for fuller body.

- Short protein rest for wheat-forward bills: 15–20 minutes at 122–131°F.

- Use rice hulls or coarser crush to avoid stuck sparges with high wheat percentages.

- Oxygenate thoroughly before pitching to support LalBrew Wit fermentation.

Attenuation Expectations and Final Gravity Targets

LalBrew Wit attenuation typically falls in the expected attenuation 75-82% range reported by yeast suppliers like Lallemand and White Labs. Use that span to plan fermentation and set realistic FG targets for witbier.

For a standard witbier with an original gravity of 1.046–1.052, aim for final gravity values near 1.008–1.012. These FG targets for witbier assume a moderate mash fermentability and a clean fermentation profile from LalBrew Wit.

Mash composition drives much of the difference between predicted and measured final gravity. A highly dextrinous mash or generous use of wheat and oats will push the final gravity higher even when LalBrew Wit attenuation is near the expected attenuation 75-82% range.

- Low-temperature, highly fermentable mash: FG closer to 1.008.

- High-mash ratio of dextrins or specialty malts: FG near 1.012 or above.

The yeast’s alcohol tolerance, listed as medium-to-high around 8–12%, allows brewers to push original gravities for stronger styles such as a weizenbock. When increasing OG, adjust target attenuation and final gravity sart to avoid unintended sweetness or over-attenuation.

Track gravity readings through primary fermentation to confirm performance against the LalBrew Wit attenuation expectation. If FG sits outside FG targets for witbier, review mash profile, pitch rate, and fermentation temperature for adjustments on the next batch.

Handling Low Flocculation and Conditioning Strategies

LalBrew Wit exhibits low flocculation, meaning its yeast remains suspended longer. This characteristic contributes to a soft, full mouthfeel and robust head retention in wheat beers. It necessitates patience when awaiting the beer's clarity.

To aid in yeast settling, consider extended cold-conditioning or brief lagering periods. Cooling the beer to 34–40°F for one to three weeks post-fermentation can expedite clearing. Secondary or bright tank storage allows suspended yeast to settle before packaging.

- Consider fining agents like Irish moss during the boil for protein clarification.

- Use gelatin or isinglass after fermentation when a clearer beer is required.

- Filtration offers the cleanest result for commercial batches that demand clarity.

Choosing the right clearing method for wheat beers depends on your desired outcome. For a soft body and strong foam, some haze is acceptable. For clearer beer, combine cold-conditioning with fining or filtration.

Effective yeast sediment management is crucial to avoid overcarbonation and off-flavors. When transferring to a bright tank, discard heavy trub and most yeast. If packaging from fermenters with high yeast levels, reduce priming sugar or allow extra settling time.

Conditioning wheat beer requires patience and careful planning. Allocate extra time for cold-conditioning and consider tank transfers to manage yeast levels at packaging. This approach maintains the beer's positive mouthfeel while addressing clarity and stability.

Packaging, Carbonation, and Shelf Stability

Choosing your packaging method early is crucial. For bottling witbier, consider the yeast's low flocculation. Use precise priming sugar calculations and keep fermentation logs to avoid overcarbonation and off-flavors.

Target carbonation levels for witbier at 2.5–3.0 volumes CO2. This range enhances coriander, orange peel, and wheat flavors, ensuring a crisp mouthfeel.

When bottle conditioning, consider live yeast counts. Cold crash gently to reduce suspended yeast without stripping delicate aromatics. Sanitation and measured priming doses help maintain consistency and safety in bottling witbier.

For kegs and bright tanks, consider forced carbonation after a short conditioning period. Allow time for flavor maturation so CO2 binds properly. If clarity is desired, settle beer until yeast levels fall before transferring for packaging LalBrew Wit beers.

Shelf stability wheat beer depends on oxygen control at packaging, alcohol level, and microbial sanitation. Keep dissolved oxygen under 50 ppb during fill. Proper packaging and cold storage slow flavor loss and haze development over time.

Higher carbonation and residual yeast can influence long-term haze and mouthfeel. Monitor stored batches and rotate stock. Good draft systems and firm packaging protocols extend quality for wheat beers fermented with LalBrew Wit.

- Check priming sugar with an online calculator or lab chart before bottling witbier.

- Measure volumes CO2 to hit desired carbonation levels for witbier.

- Use oxygen-scavenging caps or purge kegs to improve shelf stability wheat beer.

Common Problems and Troubleshooting Tips

Slow or stuck fermentation is a common issue. First, check the pitch rate, oxygenation, and mash gravity. Ensure you pitch healthy yeast at the recommended count and oxygenate the wort before pitching. Maintain fermentation temperatures between 63°–77°F for consistent yeast activity.

If fermentation stalls, gently warm the fermenter towards the lower end of the range. Swirl to resuspend the yeast. Avoid extreme temperature changes, as they can worsen fermentation problems.

Excessive esters or phenols often result from warm fermentation or stressed yeast. Lower the temperature and improve temperature control to reduce these flavors. Proper rehydration and correct pitching help create a stronger start and minimize yeast problems.

Over-temperature fermentations require immediate action. Move the fermenter to a cooler area or use a swamp cooler, chest freezer, or fermentation fridge. Rapid cooling limits off-flavors that develop when yeast run hot.

Poor clarity in LalBrew Wit is common due to low flocculation. Extend conditioning time, use finings like isinglass or gelatin, or apply gentle filtration to improve brightness. Cold-crashing for several days helps settle yeast and haze.

Off-flavors after rehydration or pitching errors can stem from incorrect rehydration temps or contamination. Rehydrate at the temperature recommended by Lallemand and use clean, sanitized equipment. Sterile technique lowers the risk of fermentation issues and unwanted sour or phenolic notes.

A brewer I spoke with pitched after rehydration at about 80°F due to cooling failures. The beer developed hot, solvent-like esters and had to be blended into a darker ale. This real-world consequence highlights the importance of backup cooling plans and access to refrigeration in saving a batch.

- Slow/stuck fermentation: check pitch rate, oxygenation, temperature.

- Too much ester/phenol: lower fermentation temp, steady control.

- Over-temperature: cool wort or fermenter quickly, monitor for off-flavors.

- Poor clarity: extend conditioning, use finings or filtration.

- Post-pitch off-flavors: follow rehydration temps and strict sanitation.

Use this troubleshooting checklist when facing LalBrew Wit troubleshooting. Careful control of pitching, temperature, and sanitation prevents most yeast problems and limits off-flavors tied to common fermentation issues.

Buying and Storage Recommendations for LalBrew Wit Yeast

Secure LalBrew Wit yeast from trusted sources like Lallemand distributors or well-known homebrew stores. Product listings frequently include customer reviews and ratings, ensuring the yeast's freshness and quality. Look for entries with around 35 reviews to gauge community feedback.

When purchasing LalBrew Wit yeast, verify the production and best-before dates. The shelf life of LalBrew Wit yeast heavily relies on storage conditions. Cold storage significantly extends its viability.

- Store dry yeast refrigerated or frozen as recommended by the manufacturer.

- Keep unopened packages cold until use to preserve cell health.

- If a packet is opened, seal it and store it chilled. Use within the manufacturer’s viability window.

Adhere to clear LalBrew storage tips: avoid temperature fluctuations and protect yeast from moisture. A small freezer stash is ideal for long-term storage. Label packages with the date received and any open-date to accurately track shelf life LalBrew Wit.

Retail considerations are crucial. Some sellers offer free shipping thresholds and promotional bundles. Choose suppliers with transparent handling and return policies when buying LalBrew Wit yeast.

Have a backup yeast option ready in case you need to pitch immediately. This prevents delays if rehydrated yeast must wait while wort cools. Proper planning reduces stress during brew day.

Follow these steps to store dry yeast safely and achieve consistent batches from LalBrew® Wit Wheat Beer Dry Yeast.

Conclusion

This Lallemand LalBrew Wit Yeast review highlights a versatile, relatively neutral wheat yeast. It provides a gentle banana-and-spice core without the heavy esters of classic hefeweizen strains. It's ideal for Belgian-style wits, American wheat beers, and recipes where adjuncts or spices dominate the aroma and flavor.

For reliable results, ferment in the 63°–77°F range. Expect 75%–82% attenuation. Note that it has low flocculation and slower settling. Follow rehydration and pitching best practices to maximize viability. Allow extra conditioning time to clarify before packaging.

Final thoughts LalBrew Wit: brewers seeking a supportive, restrained yeast should choose LalBrew Wit. Its predictable attenuation and suitable alcohol tolerance make it a practical option across many wheat-forward styles.

Further Reading

If you enjoyed this post, you may also like these suggestions:

- Fermenting Beer with Bulldog B1 Universal Ale Yeast

- Fermenting Beer with Wyeast 2042-PC Danish Lager Yeast

- Fermenting Beer with Wyeast 3763 Roeselare Ale Blend