Fermenting Beer with White Labs WLP838 Southern German Lager Yeast

Published: December 5, 2025 at 11:52:27 PM UTC

This article is a detailed guide for homebrewers and small breweries on using White Labs WLP838 Southern German Lager Yeast. It serves as a comprehensive review of lager yeast, aiming to empower you in selecting and employing WLP838 confidently.

WLP838 Southern German Lager Yeast is available from White Labs in both Vault format and an organic version. The yeast's core characteristics include an attenuation range of 68–76%, medium to high flocculation, and an alcohol tolerance of 5–10%. It thrives in temperatures between 50–55°F (10–13°C). Additionally, the strain is STA1 negative.

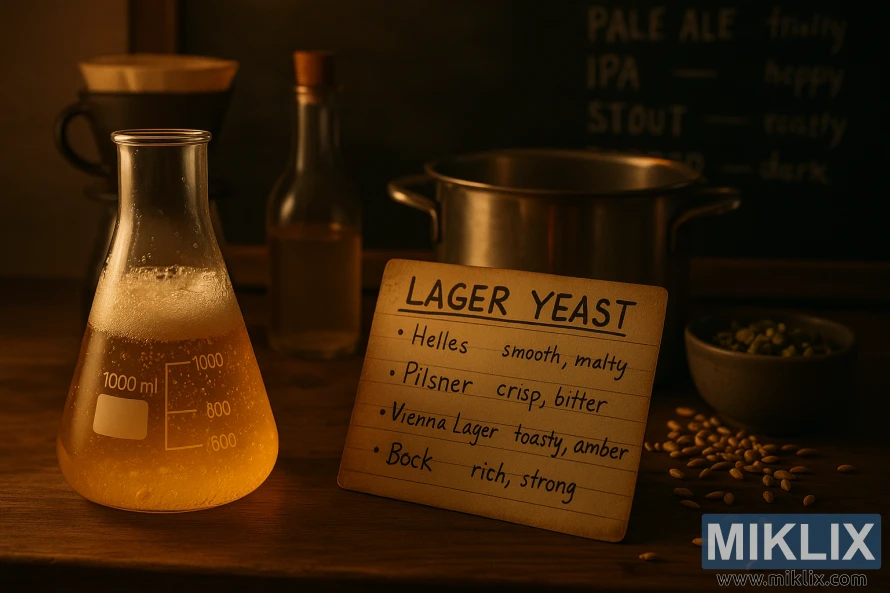

The yeast's flavor profile is malty and clean, culminating in a crisp lager finish. It may produce slight sulfur and low diacetyl during fermentation. Therefore, a diacetyl rest and sufficient conditioning are crucial. Suitable styles for WLP838 include Helles, Märzen, Pilsner, Vienna Lager, Schwarzbier, Bock, and Amber Lager.

In this WLP838 review, we will delve into fermentation temperatures and their impact on flavor, attenuation and flocculation, pitching rates and strategies, and practical yeast handling tips. Our aim is to provide clear, actionable advice for brewing beer that embodies the authentic Southern German lager character.

Key Takeaways

- WLP838 is a Southern German lager yeast from White Labs suited for classic lager styles.

- Ferment near 50–55°F (10–13°C) and plan a diacetyl rest to clean up flavors.

- Expect 68–76% attenuation, medium–high flocculation, and moderate alcohol tolerance.

- Available in Vault format and an organic option for small breweries and homebrewers.

- Use proper pitching rates and conditioning to minimize sulfur and diacetyl.

Overview of White Labs WLP838 Southern German Lager Yeast

White Labs commercial strain WLP838 comes in Vault packs and is available in organic form. It is a top choice among White Labs lager strains for those aiming at malt-focused lagers. Brewers seek it for its clean fermentation and solid clarification.

Lab notes reveal medium–high flocculation, 68–76% attenuation, and a medium alcohol tolerance of 5–10%. The recommended fermentation temperature is 50–55°F (10–13°C). The strain tests STA1 negative, ensuring no strong diastatic activity.

WLP838 is known for its malty finish and balanced aroma. It ferments reliably, sometimes showing slight sulfur and low diacetyl early on. A brief diacetyl rest and active conditioning can eliminate these off-flavors, refining the beer.

- Recommended styles: Amber Lager, Helles, Märzen, Pilsner, Vienna Lager, Bock.

- Use case: malt-forward, clean lagers where moderate flocculation aids clarity.

For brewers desiring Southern German yeast characteristics without extreme phenols or high ester loads, WLP838 is ideal. It provides dependable attenuation and a forgiving profile. This makes it suitable for both homebrewers and small breweries.

Fermentation temperature range and effects on flavor

White Labs suggests fermenting WLP838 between 50–55°F (10–13°C). This range ensures a clean, crisp lager flavor with minimal ester production. Brewers who ferment around 50°F often notice fewer solvent-like compounds and a smoother finish.

Traditionally, fermentation starts at 48–55°F (8–12°C) or allows a slight free-rise within that range. After 2–6 days, when attenuation hits 50–60%, the beer is raised to about 65°F (18°C) for a brief diacetyl rest. Then, the beer is cooled down 2–3°C (4–5°F) per day towards a lagering temperature near 35°F (2°C).

Some brewers opt for a warm-pitch method: pitching at 60–65°F (15–18°C) to shorten lag time and encourage vigorous cell growth. After about 12 hours, the tank is lowered to 48–55°F (8–12°C) to limit ester formation. The same free-rise to 65°F is used for the diacetyl rest before cooling for lagering.

The impact of temperature on lager flavor with WLP838 is evident. Cooler fermentations highlight malt clarity and subtle sulfur notes, while warmer phases increase ester levels and fruitiness. A brief diacetyl rest helps reduce buttery notes without adding esters.

- Start: 48–55°F (8–13°C) for clean fermentation.

- Diacetyl rest: free-rise to ~65°F (18°C) when 50–60% attenuated.

- Finish: step-cool to lagering near 35°F (2°C) for conditioning.

Managing the WLP838 fermentation temperature is crucial for sulfur and diacetyl levels. The strain may exhibit slight sulfur early on and low diacetyl. Long cold conditioning and careful temperature management help these compounds fade, resulting in a balanced lager with classic Southern German character.

Attenuation, flocculation, and alcohol tolerance

WLP838 attenuation typically ranges from 68 to 76 percent. This moderate dryness is perfect for Southern German lagers, such as Märzen and Helles. To achieve a drier finish, adjust mash temperatures to favor fermentable sugars. Also, plan your recipe's gravity accordingly.

Flocculation for this strain is medium to high. The yeast tends to settle clear, which accelerates conditioning and reduces clarification time. However, brewers aiming to harvest yeast should be aware of the strain's strong flocculation. This can make it challenging to collect viable cells.

The strain has a medium alcohol tolerance, roughly 5–10 percent ABV. This range is suitable for most pilsners, dunkels, and many bocks. For high-gravity beers, manage your mash profile, increase the pitch rate, and consider oxygenation. These steps support yeast performance and prevent stalled fermentations.

- Target final gravity by factoring WLP838 attenuation into recipe calculations.

- Expect clearer beer sooner thanks to favorable flocculation.

- Monitor fermentations when pushing toward the upper limit of alcohol tolerance.

Yeast performance is directly tied to brewing choices. The mash schedule, pitch rate, and temperature management all impact how closely actual attenuation matches the specification. Keep an eye on specific gravity trends and adjust conditioning time if clarity or attenuation falls short.

Pitch rate recommendations and cell counts

Mastering WLP838 pitch rate begins with a fundamental guideline. The industry standard for lagers is 1.5–2 million cells/mL/°Plato. This serves as a starting point for your brewing endeavors.

Adjustments are necessary based on the beer's gravity. For beers with a gravity up to 15°Plato, aim for 1.5 million cells/mL/°Plato. For stronger beers, increase the rate to 2 million cells/mL/°Plato. This helps prevent sluggish fermentation and off-flavors.

Temperature plays a crucial role in determining the required cell count for lagers. Cold pitches, typically between 50–55°F, benefit from higher rates, near 2 million cells/mL/°Plato. This ensures a clean and timely fermentation process.

Warm-pitching yeast for lagers allows for lower starting rates. This method encourages yeast growth. Brewers often pitch at rates around 1.0 million cells/mL/°Plato. Then, they rapidly cool the beer to limit ester formation.

- Traditional cold pitch: target ~2 million cells/mL/°Plato for WLP838 pitch rate.

- Gravity ≤15°Plato: target ~1.5 million cells/mL/°Plato.

- Warm-pitch option: reduce to ~1.0 million cells/mL/°Plato with careful temperature control.

Consider the yeast's source and viability. Lab-grown products, such as White Labs PurePitch, often have high viability and consistent cell counts. This may alter the practical pitching volumes compared to dry yeast packs.

Monitor the actual cell counts when creating starters or repitching. Prioritize healthy, active yeast over maximizing every cell in the fermenter.

Keep a record of your cell counts and fermentation results. Over time, you will fine-tune the WLP838 pitch rate for your specific equipment and recipes. This will help you achieve cleaner lagers with reliable attenuation.

Pitching strategies: traditional cold pitch versus warm pitch

Deciding between a warm pitch vs cold pitch impacts lag time, ester profile, and yeast growth. Traditional lager pitching involves adding yeast at typical lager temperatures of 48–55°F (8–12°C). Fermentation begins slowly, gradually increasing toward about 65°F (18°C) for a diacetyl rest when attenuation reaches 50–60%.

This method favors a clean profile with minimal off-flavors. It requires a slower timeline, necessitating higher pitch rates and strict temperature control. It's perfect for achieving classic lager character and minimizing yeast-derived esters.

Warm pitch strategy involves an initial pitch at 60–65°F (15–18°C). Fermentation signs appear within 12 hours, then drop to 48–55°F (8–12°C) as the yeast enters active growth. Later, free-rise to 65°F for the diacetyl rest and step-cool to lagering temperatures.

Warm pitch shortens lag time and accelerates the growth phase. Brewers can use lower pitch rates and reduce several days from the active fermentation window. Early temperature control is crucial to avoid excessive ester formation during rapid growth.

- Process note for traditional lager pitching: pitch cold, allow slow rise, perform diacetyl rest, then cool to 35°F (2°C).

- Process note for warm pitch: pitch warm, monitor for activity within ~12 hours, lower to lager-friendly temps, then perform diacetyl rest and step-cool.

When using WLP838 in either method, remember this strain can produce light sulfur and low diacetyl. Include a diacetyl rest and conditioning regardless of pitch approach. Traditional lager pitching maximizes cleanliness.

Choose warm-pitch to save time while maintaining relative cleanliness, provided you can closely monitor temperatures. Adjust pitch rate and oxygenation according to your chosen approach and beer style.

Managing sulfur and diacetyl with WLP838

WLP838 typically produces a slight sulfur note and low diacetyl during fermentation, according to White Labs. Brewers should expect these compounds early in fermentation. They must plan for targeted diacetyl management.

Start with healthy yeast, adequate oxygenation, and proper nutrient levels to reduce diacetyl formation. Pitching the correct cell count and using an active starter helps WLP838 clean up intermediate compounds more reliably.

Time the diacetyl rest when attenuation reaches about 50–60 percent. Raise the temperature to roughly 65°F (18°C) and hold for two to six days. This allows yeast to reabsorb diacetyl. Perform sensory checks during the rest to confirm progress.

If sulfur persists after primary fermentation, extended cold conditioning works well. Long lagering at near-freezing temperatures encourages volatile sulfur compounds to dissipate. Many brewers report that extended lagering plus time in keg tames WLP838 sulfur into a pleasant, low-level background note.

- Monitor attenuation and aroma at 50–60% to decide when to begin diacetyl rest.

- Use diacetyl management by holding at 65°F for 2–6 days, then cool slowly.

- Allow extended cold conditioning to reduce lager off-flavors and volatile sulfur.

Collect flocculated yeast after cooling if you plan to repitch, since recovered cells from WLP838 can remain viable. If diacetyl or sulfur issues appear, focus on longer conditioning, consistent fermentation practices, and careful sensory checks before packaging. This minimizes lager off-flavors.

Yeast handling: starters, repitching, and viability checks

Plan your starter volume to meet your target pitch rate, especially for cold-pitch lagers. A well-sized WLP838 starter for your batch size can prevent long lag times and ensure clean fermentation. For bigger batches, a robust starter or a settled harvested slurry is better than a tiny first-generation build.

Before pitching or reusing yeast, always perform viability checks. Cell counting with a hemocytometer or a cell counter, along with viability stains, gives accurate numbers. If these tools are not available, trusted lab services can test viability and offer advice specific to White Labs strains.

When repitching lager yeast, collect it after primary fermentation and the cooling phase. Allow flocculated yeast to settle, then harvest with sanitary techniques. Keep track of the generation count and viability trends to avoid using stressed or senescent yeast.

Many brewers prefer repitching a super healthy culture over a weak first-gen starter for large batches. For small first-gen starters, use them in test or small runs. If a starter shows slow activity, create a new one to avoid off-flavors.

- Sanitation: sanitize vessels and tools when harvesting and storing yeast.

- Storage: keep harvested yeast cold and use it within recommended windows to preserve viability.

- Monitoring: record viability checks and pitch rates for consistent results.

Use White Labs' pitch rate calculator for guidance when planning your WLP838 starter or repitching lager yeast. Regular yeast viability checks and disciplined handling ensure repeatable lagers and minimize fermentation problems.

Recipe guidance for styles suited to WLP838

WLP838 excels with malt-forward Southern German lagers. For Helles, Märzen, Vienna Lager, and Amber Lager, focus on Pilsner, Vienna, and Munich malts. Adjust the mash temperature to achieve the desired body: increase it for a fuller mouthfeel, decrease it for a drier finish.

When brewing Helles with WLP838, aim for a soft grain profile. Use gentle decoction or step mash for added malt complexity. Limit specialty malts to preserve the yeast's sweet, clean esters.

For pilsner recipe yeast pairing, start with Pilsner malt and German noble hops like Hallertauer or Tettnang. Target moderate IBUs to maintain malt character. High bitterness can overpower the yeast's subtle contribution.

Here are practical tips for recipe balance:

- For maltier styles like Märzen and Helles, increase Munich percentage and mash near 154–156°F for a richer body.

- For drier lagers and classic pilsner recipe yeast pairing, mash closer to 148–150°F to enhance crispness.

- Keep late hop additions restrained and use German noble varieties for authenticity.

For stronger lagers such as Bock and Doppelbock, use higher base malt and stepped mash schedules. Maintain healthy pitch rates and extended lagering to smooth alcohol and let the yeast finish cleanly.

For darker styles like Schwarzbier and Dark Lager, blend Pilsner with darker specialty malts in small percentages. This allows the yeast's soft malt expression to shine through, avoiding heavy roast levels that mask subtle esters.

Here are some simple examples:

- Helles: 90–95% Pilsner, 5–10% Vienna/Munich, mash 152–154°F, 18–24 IBU.

- Pilsner: 100% Pilsner, mash 148–150°F, 25–35 IBU with noble hops for pilsner recipe yeast pairing.

- Märzen: 80–90% Pilsner or Vienna, 10–20% Munich, mash 154–156°F, 20–28 IBU.

Follow WLP838 recipe guidance on pitch rates and temperature control to showcase the strain's clean, malty profile. With careful grain selection and balanced hopping, this yeast elevates traditional German lagers while remaining versatile for pale and darker styles alike.

Fermentation troubleshooting and common issues

WLP838 troubleshooting begins with spotting early fermentation cues. A hint of sulfur in lager often appears early and diminishes over time. To mitigate sulfur volatiles, extend cold conditioning or keg time.

Diacetyl levels, though low, are common with many lager yeasts. To address this, increase the temperature to about 65°F (18°C) for 2–6 days when attenuation hits half to three-quarters. This pause allows yeast to reabsorb diacetyl, ensuring a cleaner taste after cold aging.

Slow fermentation can indicate underpitching or temperatures that are too low. Confirm pitch rates and cell viability. Target 1.5–2 million cells per mL per degree Plato for traditional cold pitches. For a quicker start, consider a larger starter or warm-pitch strategy.

Off-esters arise from warm pitching or extended warm phases. Warm-pitching allows yeast to grow 12–72 hours before cooling to lagering temperatures. This limits fruity esters. Monitor CO2 activity and pH to time the temperature drop.

- Verify oxygenation and yeast nutrients at pitch to prevent stressed yeast and sulfur in lager.

- If fermentation stalls, slightly warm the beer and swirl to resuspend yeast before repitching.

- Use active krausen and gravity readings to confirm progress, rather than calendar days.

Resolving common lager fermentation problems requires patience and precise interventions. Small temperature adjustments, adequate nutrition, and correct pitch rates often solve issues without drastic measures. Vigilant monitoring and timely diacetyl fixes ensure consistent, clean batches.

Fast lager techniques and alternative methods

Brewers seeking quicker cellaring times turn to fast lagers and pseudo-lagers. These methods allow for faster production without long tank occupancy. Kveik lager techniques, meanwhile, use farmhouse strains at ale temperatures. They produce a cleaner, lager-like finish with careful handling.

High-pressure fermentation, or spunding, accelerates fermentation and reduces off-flavors. It keeps CO2 in solution. Start fermentation at 65–68°F (18–20°C), spund at about 15 psi (1 bar), then cool once terminal gravity nears target. This method conditions faster than traditional schedules.

WLP838 alternatives include modern strains like WLP925 High Pressure Lager Yeast and select Kveik isolates. These options provide consistent results for quick production needs. They offer lager clarity without the need for long cellar times.

Fast lager methods shorten time but alter traditional flavor profiles. Pseudo-lagers and Kveik lager methods can introduce esters or phenolics if not monitored. High-pressure fermentation reduces ester formation but requires reliable equipment and constant monitoring.

- Pros: faster throughput, reduced tank occupancy, lower energy for long cold storage.

- Cons: flavor drift from traditional Southern German character, extra equipment needs for pressure work, potential training curve.

For brewers aiming for the WLP838 Southern German profile, warm-pitching and optimized pitch rates are the best fast tweaks. These methods preserve the yeast’s hallmark sulfur management and diacetyl rest behavior. They also modestly trim the timeline.

Choose a method that aligns with your flavor goals and capacity. Opt for WLP838 alternatives when speed is crucial and traditional character is flexible. Stick to traditional practices when authenticity to style is paramount.

Comparing WLP838 to other lager strains

WLP838 is part of a collection of White Labs strains, ideal for classic German and Czech lagers. Brewers often compare WLP838 to WLP833 for malt-forward styles like Helles and Märzen.

WLP838 offers a soft, malty finish with balanced aroma. WLP833, known for Ayinger and German bock profiles, brings a unique ester set. This comparison aids brewers in selecting the right strain for their recipes.

Technically, WLP838 has an attenuation of about 68–76% and medium-high flocculation. This affects body and clarity. Other strains might ferment cleaner at lower temps or result in a drier beer. Noting these differences is crucial for achieving the desired final gravity and mouthfeel.

When selecting yeast, it's important to match the strain's character to the regional style. Use WLP838 for southern German, malt-forward lagers. For a crisper Pilsner or Czech nuance, opt for WLP800 or WLP802. Blind trials and split batches can reveal subtle but significant differences in aroma and finish.

For recipe planning, consider attenuation and temperature ranges. Track differences in lager strains during fermentation. Adjust pitching rate, temperature profile, and conditioning time accordingly. Small experiments with WLP838 vs WLP833 will help determine which strain best suits your flavor goals.

Practical yeast management for homebrewers and small breweries

Starter sizing and generation control are crucial. For cold lager fermentations, aim for a starter or pitch volume that meets your cell count targets. Weak first-generation starters struggle with large 10–20 gallon batches. If scaling is needed, expand the starter over generations or use a healthy harvested cake.

Harvesting timing is linked to flocculation. WLP838 has medium–high flocculation, so collect yeast after cooling when it has compacted. Store harvested slurry cold and track generation counts to avoid loss of vigor. Good records help decide when to refresh from a store-bought culture.

Always check viability before repitching. A simple methylene blue or microscope check saves batches. Monitor dissolved oxygen and add yeast nutrient during wort prep for clean fermentations.

Keep a detailed log of pitch rates, fermentation temperatures, attenuation, diacetyl rest timing, and conditioning. Note any deviations and the resulting flavor. Detailed notes help reproduce successes and pinpoint problems during scaling.

Small breweries can adopt warm-pitch or controlled temperature ramps to manage timelines without sacrificing beer quality. Consider lab-grown products like White Labs PurePitch for predictable cell counts and consistent viability when demand grows.

Practical steps to follow:

- Calculate starter size per batch instead of guessing.

- Harvest after flocculation and cool the slurry quickly.

- Test viability before repitching WLP838 or other strains.

- Keep nutrient and oxygenation checks standard in your SOPs.

- Record every generation and pitching event for repeatability.

Adopting these practices improves consistency for both hobbyists and small brewery teams. Clear yeast harvesting methods and careful repitching WLP838 choices reduce off-flavors and speed reliable production.

Equipment and timeline recommendations for lagering with WLP838

Before brewing, select dependable lager equipment. A temperature-controlled fermentation vessel, like a ferm chamber or jacketed tank, is ideal. Ensure you have an accurate thermometer and controller for precise temperature control. For those interested in pressure lagers, a spunding valve is a good investment. Additionally, having access to a hemocytometer or yeast viability service can help refine your pitch rates.

Begin fermentation at 50–55°F (10–13°C) for a traditional profile or opt for a warm-pitch approach for a quicker primary. Keep a close eye on gravity and attenuation. Documenting your progress ensures a consistent WLP838 lagering timeline.

- Allow primary fermentation to progress based on activity and gravity readings.

- Once attenuation reaches 50–60%, increase temperature to about 65°F (18°C) for a 2–6 day diacetyl rest.

- After the rest and near terminal gravity, start step-cooling at 2–3°C (4–5°F) per day until reaching lagering temperature of ~35°F (2°C).

Cold conditioning the beer for the style's required time is crucial. Weeks to months of lagering can significantly reduce sulfur and refine flavors. While fast timelines like warm-pitch plus pressure fermentation are possible, a diacetyl rest schedule and some cold conditioning are necessary for WLP838 to achieve the desired cleanliness.

Sanitation and yeast health are key to avoiding fermentation stalls or off-flavors. Regularly check your controllers and sensors. Extended keg time and patient lagering help in sulfur dissipation, a common outcome when equipment and timeline are well-aligned.

Conclusion

WLP838 Southern German Lager Yeast from White Labs offers a classic, malt-forward profile when handled with care. It thrives between 50–55°F (10–13°C), achieving moderate attenuation (68–76%) and medium–high flocculation. This makes it ideal for Helles, Märzen, Vienna, and traditional Bavarian styles, where a clean, malty finish is sought.

This Southern German lager yeast review emphasizes the importance of following best practices with WLP838. Adequate cell counts and a warm pitch can speed up fermentation. A diacetyl rest at about 65°F (18°C) for 2–6 days is crucial. Extended lagering and controlled cooling help eliminate sulfur and refine the beer's body. Prioritizing yeast health, viability checks, and steady temperature control ensures consistent results.

Practical takeaways: WLP838 can handle moderate alcohol and adapts across lager types, producing subtle differences, especially in malt-driven recipes. By following the outlined pitching, resting, and conditioning steps, you can highlight the authentic Southern German character. This will help achieve dependable, repeatable beers.

Further Reading

If you enjoyed this post, you may also like these suggestions:

- Fermenting Beer with Bulldog B16 Belgian Saison Yeast

- Fermenting Beer with White Labs WLP500 Monastery Ale Yeast

- Fermenting Beer with Wyeast 1332 Northwest Ale Yeast