Fermenting Beer with Wyeast 1203-PC Burton IPA Blend Yeast

Published: January 2, 2026 at 3:34:25 PM UTC

Wyeast 1203-PC Burton IPA Blend Yeast is a seasonal liquid strain designed to revive the historic English IPA character. It's chosen by brewers to enhance hop bitterness and aroma. This allows pale malts and a classic Burton water profile to shine through.

The blend offers low to moderate esters, which can be adjusted with fermentation temperature and pitching rate. It typically attenuates at 71–74%, with medium-high flocculation. It can handle up to 10% ABV, making it ideal for cask conditioning and stronger session beers.

Available seasonally, this strain is often paired with historical recipes. It excels in recreations of 19th-century English IPAs and versatile styles like Best Bitter, Porter, and Foreign Extra Stout. Proper handling, including starters, cleanliness, and cautious home culturing, helps preserve its vitality when fermenting Burton IPA or reusing the culture.

Key Takeaways

- Wyeast 1203-PC Burton IPA Blend Yeast revives historic English IPA character.

- Expect 71–74% attenuation, medium-high flocculation, and 64–74°F optimal range.

- Fermentation temperature and pitch rate control ester profile and finish.

- Seasonal availability means planning is key when sourcing Burton IPA yeast.

- Good starter practices and cleanliness improve results and reuse potential.

Why Wyeast 1203-PC Burton IPA Blend Yeast is ideal for historic English IPA brewing

Wyeast 1203-PC Burton IPA blend was designed to bring back the essence of Victorian-era English IPAs. It showcases hop bitterness and aroma, allowing Kent Goldings and other traditional hops to stand out. This clarity is key to replicating the authentic Burton IPA in today's brews.

The blend's ester production is in a low to moderate range. Brewers can adjust fruitiness by tweaking fermentation temperature and pitching rate. This flexibility results in a palate that's neutral to mildly fruity, perfect for pale malts and a robust malt backbone.

Its medium-high flocculation makes it ideal for cask conditioning and clear beers. Proper yeast handling and starter practices, supported by lab work, enhance viability and consistency. These steps help avoid stuck fermentations and ensure the yeast consistently produces Burton IPA characteristics.

When used with a traditional recipe and a water profile that mirrors Burton-on-Trent's mineral profile, the strain enhances hop bite while preserving malt depth. The outcome is a balanced bitterness, aroma, and finish reminiscent of historic English IPA brewing.

Vital stats every brewer should know about this strain

Wyeast 1203 specs are straightforward and useful for planning an English IPA. Apparent attenuation sits between 71–74%, which gives a balanced finish. This balance leaves enough malt body without excessive sweetness.

Flocculation is rated medium–high, so the yeast clears well for cask and bottle conditioning. Good flocculation helps with brightness and presentation in traditional Burton-style ales.

Target ferment temp ranges from 64–74°F (18–23°C). Staying within this ferment temp band controls ester production. It keeps the palate finish neutral to mildly fruity.

ABV tolerance is listed up to 10% ABV, making the blend sturdy enough for stronger English ales. Brewers aiming for higher strengths should mind pitch rate and oxygenation.

- Attenuation: reliable 71–74% apparent for predictable final gravity.

- Flocculation: medium–high for good clarity and cask suitability.

- Ferment temp: 64–74°F to manage ester profile and drying.

- ABV tolerance: up to 10% ABV with proper starter and sanitation.

To hit the listed Wyeast 1203 specs, use healthy starters, clean technique, and appropriate pitching rates. These steps support the strain reaching its expected attenuation and consistent fermentation behavior.

How to prepare and rehydrate Wyeast 1203-PC Burton IPA Blend Yeast for best results

Begin with clean equipment and a cool, controlled environment. Wyeast 1203, a liquid seasonal blend, requires careful handling. Proper preparation preserves viability and controls the beer's ester profile.

For small-scale recovery, start with a mini inoculum. Place about 0.5 mL of culture into 5 mL of 1.040 wort. Allow it to reach max density over roughly three days. This step reduces shock and builds a healthy population before scaling up.

When expanding, aim for a single-step starter sized to your batch. Use a 2–4 L starter on a stir plate for typical 5‑6 gallon Burton IPA wort. This method yields high viability without complex step-starter sequences. Good yeast pitching prep keeps ester formation predictable at low to moderate levels.

Check cell counts and viability before pitching. Healthy cell numbers are vital for hitting target attenuation. Adjust starter volume if counts fall short to avoid sluggish fermentation or unwanted esters.

- Sanitation: sterilize flasks, caps, and transfer tools.

- Temperature: ferment starters at the yeast’s preferred range to avoid stress.

- Oxygenation: properly aerate the final wort before pitching the starter.

For home culturing, store small test tubes with ~1 mL of cooled sterile water and a bit of culture in the fridge. This creates a compact yeast bank that can keep Wyeast 1203 viable for multiple years. Use these samples to seed future liquid yeast starter builds safely.

When rehydrating Wyeast 1203 from a smack pack or vial, follow a gentle approach. Gradually acclimate cells to wort temperature by slow addition of small volumes. This reduces thermal and osmotic shock and improves initial activity.

Plan your timeline around yeast pitching prep. Allow time for the starter to peak and settle. Pitch during active growth or just after the starter begins to drop. This timing ensures vigorous fermentation and consistent attenuation for Burton IPA character.

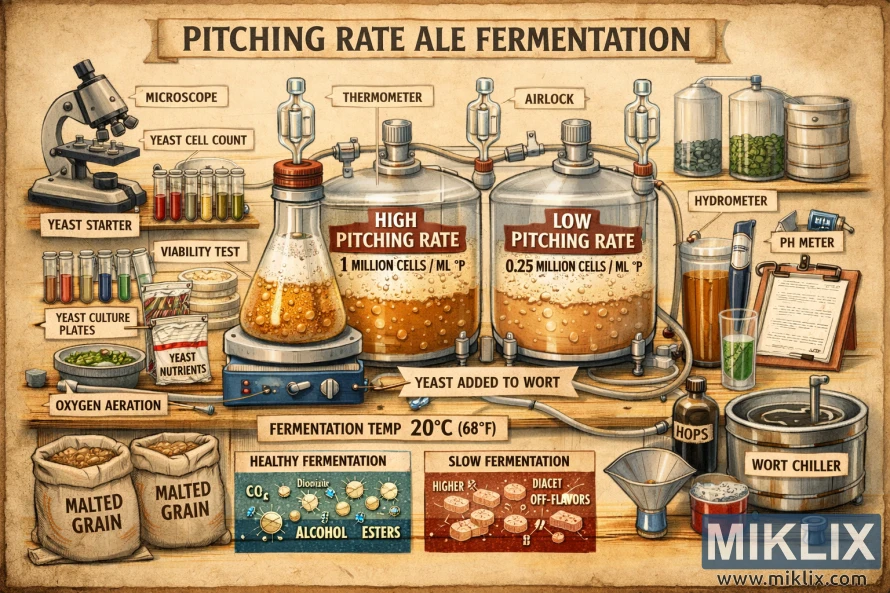

Pitching rate and cell counts tailored to Burton IPA styles

To achieve the perfect pitching rate for Burton IPA, it's crucial to set clear goals for ester expression. Lower pitch rates, combined with slightly higher fermentation temperatures, enhance fruity esters. Conversely, higher pitch rates suppress these esters, resulting in a cleaner, malt-forward profile characteristic of classic Burton IPAs.

When calculating yeast cell counts, consider your batch size and gravity. For a 5-gallon, OG 1.064 Burton IPA, aim for a healthy cell count to ensure proper attenuation and handle the high IBU load. Use standard calculators or cell count charts for an English ale pitch rate, then adjust upward for the higher gravity.

Plan your starter size for Wyeast 1203 to achieve the desired viability and population. A practical approach is to start with a small inoculum in 5 mL of 1.040 wort to build a dense culture in about three days. Then, scale up this culture into a final starter of 2–4 L on a stir plate to reach high viability above 90%.

When deciding on final pitch timing and volume, remember to keep pitching for esters in mind. For more ester character, pitch at the lower end of recommended cell counts and accept a slightly slower start. Conversely, for restrained esters and crisper bitterness, pitch heavier and keep fermentation cooler early on.

- For low-to-moderate esters: reduce pitching rate slightly and ferment a few degrees warmer.

- For clean English character: increase yeast cell counts and pitch a well-grown starter.

- Sanitation: maintain strict cleanliness when building starter size Wyeast 1203 to preserve viability above 95%.

After pitching, monitor activity closely. A vigorous, healthy start indicates you've met your target cell counts and pitching rate Burton IPA needs. Adjust future batches based on lag time, attenuation, and sensory cues to refine pitching for esters in subsequent brews.

Fermentation temperature strategies to control esters and attenuation

Before pitching, set a clear target. For Wyeast 1203, the ideal fermentation temperature ranges from 64–74°F (18–23°C). Choosing a temperature within this range allows you to control esters and flavor profile effectively.

To highlight hop bitterness and maintain clean flavors, aim for the lower end. Keeping fermentation between 64–68°F suppresses fruity esters. This results in a neutral finish that complements the forward hopping in traditional Burton IPA recipes.

For a softer, fruitier note, aim for the higher end of the range. Fermenting closer to 70–74°F encourages mild esters. These add a subtle fruit character without overwhelming malt and hops.

Pitching rate and yeast health are crucial. A healthy, high-viability starter reduces lag time. It also helps with attenuation control in Burton IPA by preventing stress-driven ester spikes and ensuring expected attenuation near 71–74%.

- Target low-mid range (64–68°F) for cleaner beer and crisper hop presence.

- Target upper range (70–74°F) for gentle fruity esters and softer balance.

- Use a proper starter and maintain steady temperature to protect attenuation control Burton IPA and avoid wild swings.

Keep a close eye on temperatures during peak activity. Avoid sudden rises that can boost ester production and stall attenuation. Employ a reliable controller or swamp cooler to maintain a consistent fermentation temperature for Wyeast 1203.

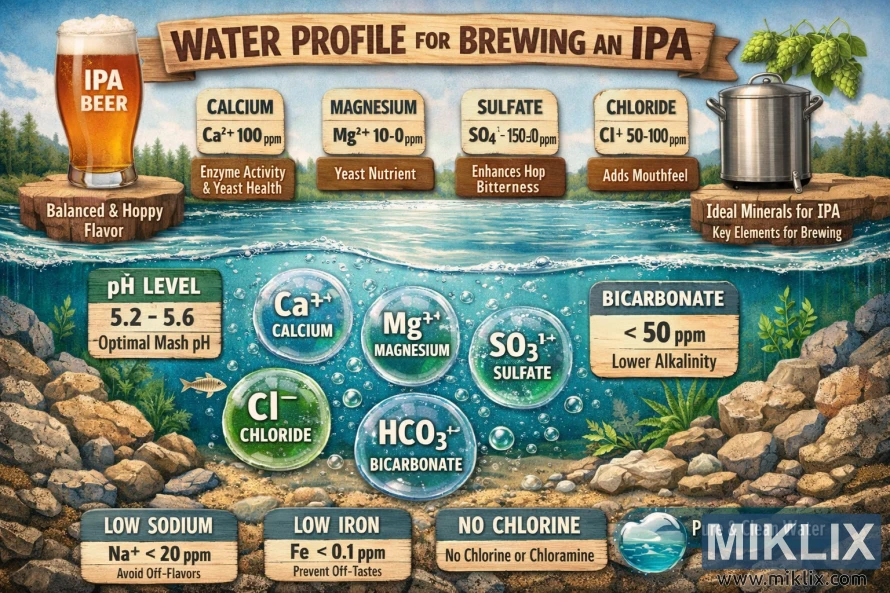

Water profile and mash suggestions to complement Burton IPA character

Wyeast 1203 enhances classic water styles and pale malts. A Burton water profile amplifies hop bite and crisp finish. Brewers aim for higher sulfate levels to emphasize hop clarity, ensuring a balanced pale malt backbone.

To achieve the desired sulfate/chloride ratio IPA, target a higher sulfate level than chloride. Aiming for a sulfate-to-chloride ratio favoring sulfate enhances dryness and sharp bitterness. This complements the clean cut of Kent Goldings and other English hops against the malt.

For mash suggestions, aim for a single-infusion mash between 148–152°F. A 148°F mash results in a drier beer, leveraging the yeast's 71–74% attenuation. A 152°F mash preserves body, balancing the heavy hopping with a robust pale malt backbone.

Use high-quality pale malt as the base, with a modest amount of specialty grains like Biscuit and Crystal 60L. These grains add color and toasty notes without dominating the malt profile. Adjust the specialty grain percentage to achieve OG ~1.064 and SRM 12–16 for a traditional Burton-style IPA.

- Water: emulate Burton with elevated sulfates and moderate chlorides.

- Mash temp: 148°F for drier finish; 152°F for more body.

- Malt bill: strong pale malt backbone with 5–10% specialty grains.

Balance is key. Match the sulfate/chloride ratio IPA to your hop load and choose a mash schedule that supports the desired mouthfeel. This way, the yeast showcases both hop crispness and malt character, traditional to Burton IPAs.

Hop selection and hopping schedule to work with Wyeast 1203-PC Burton IPA Blend Yeast

Opt for English hops to complement the yeast's classic character. Traditional Burton India Pale Ales use Kent Goldings or East Kent Goldings. These hops add gentle floral and earthy notes, enhancing the Wyeast 1203 hop balance.

Start building bitterness early in the boil to aim for 70–80 IBUs. The Wyeast 1203 blend emphasizes hop bitterness. Thus, heavy kettle additions are crucial. They establish the backbone, allowing pale malts and water profile to shine without overpowering malt character.

For flavor, add hops mid-boil, around 20–30 minutes before the end. This approach adds depth without introducing modern citrus-forward intensity. A conservative late-hop plan helps preserve traditional English aroma.

Keep late additions and dry hopping minimal for an authentic Burton IPA. Small dry-hop doses can enhance the scent. However, restrained use ensures the brewer's intent is preserved, aligning with malt and minerality.

- Early: large charge for bitterness to meet hopping schedule Burton IPA targets.

- Mid: measured additions for classic hop flavor.

- Late: light or no additions to avoid fruity, modern IPA character.

- Dry hop: optional and minimal when using Kent Goldings.

Pair hop choices with a solid malty backbone to balance bitterness. This approach ensures the hop selection and yeast's moderate ester profile create a historically accurate Burton IPA.

Recipe example and expected fermentation numbers

Start with this Burton IPA recipe for a 5-gallon batch, inspired by 1800s East India ales. The all grain bill includes Maris Otter base malt, Biscuit, and Crystal 60L. These ingredients create a rich, malty backbone that complements strong Kent Goldings hopping.

Target specs for this Wyeast 1203 example recipe are an original gravity (OG) near 1.064 and a final gravity (FG) around 1.016. With Wyeast 1203’s typical attenuation of 71–74%, the OG FG expected numbers align with a balanced 6.1% ABV finished beer. It also has roughly 74 IBUs of perceived bitterness.

- Grain: Maris Otter 10 lb, Biscuit 1 lb, Crystal 60L 1 lb (adjust for yield).

- Hops: Kent Goldings bittering at 60 min, late additions to total ~74 IBU.

- Water: Burton-style salts to accentuate malt and hop bite.

To ensure reliable performance, build a starter on a stir plate and scale to 2–4 L. This boosts cell count. A healthy starter reduces lag and helps Wyeast 1203 reach its attenuation range. This results in a clean fermentation with mild fruitiness.

Ferment between 64–74°F and monitor gravity. If fermentation stalls above target FG, check pitch viability and temperature. When the numbers match the OG FG expected numbers, proceed to conditioning. This allows malt and hops to marry.

This Wyeast 1203 example recipe offers a clear path to an authentic Burton IPA recipe. It showcases a malty core, English hop character, and predictable fermentation outcomes. This is achieved when yeast handling and temperatures are controlled.

Managing flocculation and conditioning for clarity and cask suitability

Wyeast 1203 exhibits medium–high flocculation, aiding yeast drop post-primary fermentation. This characteristic enhances beer clarity without the need for heavy fining. It aligns well with traditional all-grain Burton IPA methods.

Conditioning Burton IPA requires gentle cold storage or a brief cellar time for yeast settlement. Moderate attenuation in this blend benefits from additional time. This allows bitterness to round and malt character to deepen.

For cask conditioning, ensure live yeast and nutrient levels are adequate for natural carbonation. Avoid aggressive filtration, as it strips out beneficial yeast cells. This approach is crucial for cask conditioning success.

When transferring casks, handle them with care to prevent oxygen pickup and sediment disturbance. During rousing or tapping, proceed slowly. This helps keep settled yeast in the cask, preserving natural conditioning and beer clarity.

Simple practices can enhance results:

- Cold condition at cellar temps for several days to a few weeks to improve clarity and mellow flavors.

- Use a mild fining only if clarity is still an issue; strong filtration reduces cask conditioning potential.

- Retain trub and yeast when appropriate to support secondary conditioning Burton IPA styles.

Monitor clarity visually and by taste rather than chasing a sterile look. Let flocculation Wyeast 1203 and thoughtful cask conditioning work together. They deliver a clear, balanced pint, perfect for traditional service.

Common fermentation issues and troubleshooting with this blend

Wyeast 1203 troubleshooting often starts with temperature and pitching rate. Fermenting at the high end of the yeast's range or underpitching can boost esters. This results in fruity notes that overpower the malt and hops.

Low cell counts or a weak starter increase the risk of off-flavors and incomplete attenuation. A well-sized single-step starter on a stir plate maximizes viability and reduces lag time before active fermentation begins.

High hopping levels in Burton-style recipes can stress yeast. Heavy IBUs around 70 or more demand strong yeast health, good oxygenation at pitch, and proper nutrients to hit expected attenuation near 71–74%.

If fermentation problems Burton IPA brewers face include sluggish activity, check viability and oxygenation first. Take gravity readings to confirm progress. If gravity stalls, consider a nutrient addition or a measured re-pitch of a healthy, active strain.

- Monitor temperature closely to limit excessive ester production.

- Scale the starter to match original gravity and hopping intensity.

- Oxygenate wort at pitch to support a clean, steady ferment.

When a stuck fermentation appears, avoid panicked interventions. Measure cell counts if possible. Warm the fermenter slightly within the yeast's safe range and gently swirl to resuspend yeast. If stuck fermentation persists, re-pitch with fresh, active cells prepared in a vigorous starter.

Strict sanitation prevents contamination that causes off-flavors unrelated to yeast stress. Clean equipment, maintain good starter hygiene, and discard compromised starters to protect batch quality.

For persistent issues, record mash pH, water profile, and hop additions for each batch. Detailed notes help identify patterns and inform future Wyeast 1203 troubleshooting, reducing the chance of recurrent fermentation problems Burton IPA recipes can expose.

Home culturing and reuse recommendations for Burton IPA blend

Wyeast 1203-PC Burton IPA Blend is often seasonal, prompting brewers to home culture it for future batches. A small yeast bank is essential for maintaining reliable cells without the need for lab equipment.

To start, save liquid yeast from a successful fermentation. Remove most of the beer, leaving about 1 mL with the yeast. Then, add 10–50 mL of cooled, sterile water to a small tube or vial. Mix gently and refrigerate. This basic setup can keep yeast stable for months and usable for up to two years with proper care.

For a culture, shake the banked vial and transfer about 0.5 mL into 5 mL of 1.040 wort. Allow it to grow to full density over three days. Scale up from this mini culture to a 2–4 L starter on a stir plate. This will help you achieve the cell counts needed for a Burton IPA.

Avoid glycerol stocks if you don't have -80°C storage. Skip plating or slants unless you plan regular reculturing and can maintain sterile technique. These methods add unnecessary complexity and time for most homebrewers.

- Keep sanitation strict during transfers to reduce contamination risk.

- Label vials with date, strain, and original batch to track age and performance.

- Rotate your yeast bank by making fresh starters every few cycles to maintain vitality.

When reusing liquid yeast, check its aroma and growth in a starter. If it shows off-flavors or slow growth, discard it and get a fresh pack. Good practice and modest record keeping can extend Wyeast 1203's life for many brews.

These steps for reusing liquid yeast and making starters provide a practical way to preserve the Burton IPA character. A modest yeast bank not only saves money but also keeps your favorite strain ready for future batches.

Comparing Wyeast 1203-PC Burton IPA Blend Yeast to other English and IPA yeast strains

Wyeast 1203 is designed to highlight hop bitterness and aroma. It allows pale malts and a Burton-style water profile to shine. This places it between classic British character and a more hop-forward IPA yeast. It's ideal for brewers aiming for cask-ready clarity without heavy fruity esters.

Compared to strains like Wyeast 1968 London ESB or Wyeast 1098 British Ale, 1203 has less raisin and dried-fruit esters. These strains offer fuller malt presence and bolder English fruit. In a glass, 1203's focus on bitterness and hop aroma stands out against many traditional English isolates.

Practical handling is similar across strains, but Wyeast 1203's seasonal availability prompts brewers to explore alternatives. For a cleaner palette, Wyeast 1056 American Ale is a good choice. For a stronger English stamp, 1968 or 1098 are better options. Each choice impacts attenuation, flocculation, and final mouthfeel.

- Hop expression: Wyeast 1203 highlights late-hop character more than many British strains.

- Ester profile: Lower to moderate in 1203 compared to high-ester English yeasts.

- Flocculation and clarity: Medium-high in 1203, ideal for cask or conditioned beers.

- Alternatives: Wyeast 1968, 1098, and 1056 serve different goals in English ale yeast comparison.

Brewers should match yeast traits to recipe goals when choosing between Burton IPA and other yeasts. If hop bite and pale malt shine are key, compare Wyeast 1203 with alternatives. This comparison ensures the desired ester level and attenuation. It helps select the right strain for a historic English IPA or a modern hop-forward take.

Conclusion

Fermenting with Wyeast 1203 combines the essence of English IPA with the precision of modern brewing. This yeast strain offers low-to-moderate esters, 71–74% attenuation, and medium–high flocculation. It's perfect for pale malt and Kent Goldings hopping. Brewers aiming for a true Burton IPA can achieve predictable results with the right water treatment and mash design.

Success hinges on good lab technique. A healthy starter, strict sanitation, and precise cell-count pitching are crucial. This approach minimizes off-flavors, ensuring balanced bitterness and aroma. When using Wyeast 1203, monitor temperatures and plan your hopping carefully. Early bittering and late aroma additions preserve hop clarity, honoring the style's heritage.

Reuse and home culturing can extend Wyeast 1203-PC Burton IPA Blend's availability. Consistent starter practice and viability monitoring are key. Homebrewers can reliably replicate classic East India IPA profiles, with OG/FG near 1.064→1.016 and around 6% ABV. In summary, careful pitching, water chemistry, and fermentation control are essential for authentic Burton IPA brewing.

Further Reading

If you enjoyed this post, you may also like these suggestions:

- Fermenting Beer with White Labs WLP400 Belgian Wit Ale Yeast

- Fermenting Beer with Lallemand LalBrew BRY-97 Yeast

- Fermenting Beer with Wyeast 1084 Irish Ale Yeast