Fermenting Beer with Wyeast 1187 Ringwood Ale Yeast

Published: January 1, 2026 at 8:08:49 PM UTC

Wyeast 1187 Ringwood is a liquid ale yeast strain with a rich history in English-style brewing. It's prized for its balance of fruity esters and malt complexity. This makes it ideal for bitters, porters, and brown ales.

Wyeast 1187 is a liquid yeast strain known for its high flocculation and typical attenuation of 68–72%. It can tolerate up to about 10% ABV and prefers a fermentation range of 64–74°F (18–23°C). Expect fruity esters with malty, nutty, and toffee notes, and a tendency to clear well when allowed to flocculate.

Practical notes: Ringwood can be a slow starter and a slower fermenter. It often benefits from a slightly larger starter and patient timing. This review will outline fermentation control, recipe fits, and common troubleshooting to help you get the best results when fermenting with Ringwood.

Key Takeaways

- Wyeast 1187 Ringwood Ale Yeast produces fruity esters with malty, toffee-like complexity.

- Attenuation commonly sits near 70% with high flocculation and good natural clarity.

- Recommended fermentation range is 64–74°F (18–23°C); alcohol tolerance up to 10% ABV.

- Slow starting behavior means a starter and patience improve outcomes.

- This Ringwood 1187 review focuses on practical management and recipe pairing for clear, balanced ales.

Overview of Wyeast 1187 Ringwood Ale Yeast

Wyeast 1187 Ringwood is a liquid ale yeast strain with a rich history in English-style brewing. It's prized for its balance of fruity esters and malt complexity. This makes it ideal for bitters, porters, and brown ales. The Ringwood Ale overview showcases its traditional use and versatility in various recipes.

Wyeast 1187 characteristics include high flocculation, aiding in natural beer clarity. Attenuation is typically around 70%, with a range of 68–72%. It can tolerate up to 10% ABV, allowing for stronger ales without compromising character.

This strain prefers fermentation temperatures between 64–74°F (18–23°C). It can be slow to start, so proper pitching and healthy starters are crucial. Expect a calm, steady fermentation process that rewards patience and proper yeast care.

It's commonly used in English pale ales, bitters, and southern English brown styles. Brewers also employ it in American IPA, oatmeal stout, and fruit beers for its malty backbone and gentle esters. The Ringwood Ale overview remains relevant for both traditional and crossover recipes.

- Form: liquid ale yeast Ringwood, supplied as a live liquid culture

- Fermentation temp: 64–74°F (18–23°C)

- Attenuation: ~70% (68–72% typical)

- Alcohol tolerance: ~10% ABV

- Flocculation: high, aids natural clarity

Understanding Wyeast 1187 characteristics is key to selecting the right mash profile and pitching strategy. Small adjustments to temperature and oxygenation can enhance esters or focus on malt. This makes the liquid ale yeast Ringwood a versatile tool for many ale recipes.

Flavor Profile and Fermentation Characteristics

Wyeast 1187 offers a distinct Ringwood flavor profile, a favorite among brewers of traditional English ales. It produces fruity esters reminiscent of bright citrus or grapefruit. This adds a lively top note to pale ales, enhancing their character without overpowering the hops.

The yeast also contributes subtle nutty toffee flavors, enriching the malt depth. These flavors complement the esters, rounding out the midpalate. This is particularly beneficial for darker beers like brown ales and stouts, adding complexity.

Fermentation with this strain is notable for its slow start and deliberate pace. Patience is key, as it leads to cleaner esters and a smoother finish. This careful approach ensures a refined beer.

At moderate temperatures, the fruity esters harmonize with a solid malty backbone. This balance prevents the beer from feeling one-dimensional, while maintaining its body and drinkability.

Extended fermentation enhances ester development and improves clarity by allowing yeast to drop bright. This understanding is crucial for brewers, guiding them on when to expedite fermentation and when to let the beer mature naturally.

- Primary notes: grapefruit-like fruity esters paired with subtle nutty toffee flavors.

- Balance: esters complement malt without overwhelming it, preserving body.

- Fermentation tips: expect slow start; allow extra time for full expression.

Fermentation Temperature Range and Control

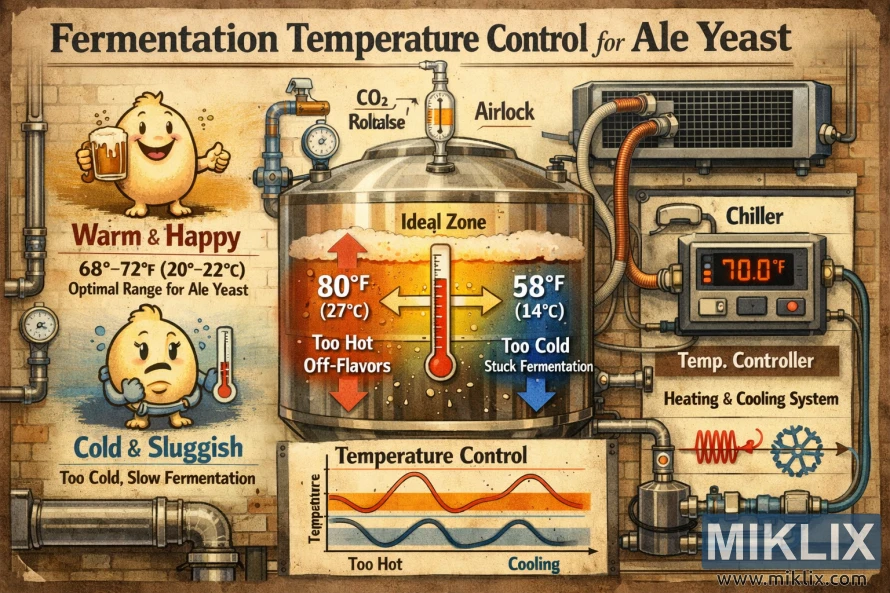

Wyeast 1187 excels when the wort temperature stays within a specific range. Target 64–74°F for optimal results. This range balances clean fermentation with the right amount of esters.

Lower temperatures result in cleaner beers with moderate esters. Moving towards the higher end enhances fruitiness and ester presence. This is ideal for pale ales and IPAs, adding notes of grapefruit or tropical flavors.

Effective temperature control prevents off-flavors like fusel alcohols and solvent notes. Avoiding sudden temperature changes is crucial. It helps yeast perform well and avoids unwanted byproducts. Keep the temperature steady during both the main fermentation and the tailing phases.

- Use a fermentation chamber or temperature-controlled fridge to hold 64–74°F reliably.

- Heat belts or wrap-around heaters work for cooler basements when set with a thermostat.

- Place the fermenter away from drafts and sun to avoid short-term spikes.

Adjust target temperatures based on your beer style. For English bitters or porters, aim for the lower-to-mid range to keep esters in check. For pale ales or IPAs, aim for the mid-to-upper range to enhance fruity esters.

Monitor temperatures with a probe and log readings daily. Small adjustments early in fermentation have the greatest impact on ester production. Proper temperature management ensures consistent flavor and cleaner finishes with Ringwood.

Attenuation, Alcohol Tolerance, and Body

Ringwood attenuation for Wyeast 1187 falls within a moderate range. Homebrewers often observe values between 68–72 percent. Thus, Wyeast 1187 attenuation 70 is a consistent outcome under optimal fermentation conditions.

The level of attenuation results in a beer body with some residual sugars. This characteristic supports the yeast's nutty and toffee notes, preventing the beer from becoming overly sweet.

This strain can tolerate alcohol up to about 10% ABV. Brewers can experiment with high-gravity recipes. However, it's crucial to plan for extended fermentations to safely reach the 10% ABV alcohol tolerance.

Recipe choices significantly impact the beer's final feel. A highly fermentable mash will lower the final gravity and make the beer body slimmer. To enhance body while maintaining typical Ringwood attenuation, consider using a shorter mash or adding dextrin malt.

Simple adjustments can offer control:

- Raising the mash temperature increases residual extract and enhances the beer body.

- Adding oats or cara-pils can improve mouthfeel without significantly altering the gravity.

- For high-gravity brews, step-feeding or oxygenation can help meet the 10% ABV alcohol tolerance target.

Expect a balanced final gravity with enough malt character to complement the strain's flavor profile. Matching mash fermentability and adjuncts to desired Ringwood attenuation will help achieve both flavor and mouthfeel goals.

Flocculation and Clarity Management

Wyeast 1187 exhibits high Ringwood flocculation, allowing yeast to settle out of suspension cleanly. This characteristic is a boon for brewers aiming to achieve bright beers without the need for heavy filtration.

To safeguard beer clarity, it's crucial to plan for extended conditioning post-fermentation. A few days of cold conditioning can expedite yeast settling, crucial for the clear appearance many beer styles demand.

- Allow at least 5–14 days of conditioning before packaging for best results.

- Cold crash for 24–72 hours to encourage rapid settling of yeast and haze particles.

- Avoid excessive rousing during transfers; gentle siphoning leaves most trub behind.

Effective yeast flocculation management hinges on gentle handling and precise timing. Utilizing Wyeast starters or healthy pitch rates ensures even fermentation. Then, the high flocculation rate takes over, clarifying the beer.

When packaging, expect some sediment in bottles or keg dip tubes. Leave most solids behind during racking. Use a fine filter only if absolute clarity is necessary for commercial presentation.

Fermentation Timing and Patience

Wyeast 1187 often defies the standard two-week fermentation timeline. Brewers frequently find that Ringwood fermentation time is better extended. Aiming for about three weeks of primary fermentation is advisable. This allows flavors to mature and haze to settle.

Some batches may experience a slow start with this strain. A slow starter Ringwood can still be managed to reduce lag and enhance yeast health. However, it might not completely eliminate delayed activity. Ensuring proper oxygenation, maintaining temperature control, and using an adequate pitch are crucial for yeast activation.

When signs of fermentation are faint, rely on precise measurements. Instead of relying solely on bubbles or krausen, take gravity readings. Regularly checking gravity readings provides accurate insights into fermentation progress and when it reaches its final gravity.

Extended fermentation is beneficial for cooler or high-OG beers. Allowing the beer to sit for four weeks in primary or conditioning can refine esters and enhance clarity. Tasting during this period allows for the assessment of development without over-manipulating the beer.

- Tip 1: Measure gravity at day 3, day 7, and before bottling to track drift.

- Tip 2: If gravity stalls, warm the fermenter slightly and swirl to wake yeast.

- Tip 3: Use a viable starter for a consistent slow starter Ringwood performance.

Patience is key when working with this yeast. Allowing more time for Ringwood fermentation and opting for extended fermentation when necessary results in cleaner profiles and fuller maturation. Rely on gravity readings and taste notes over surface activity when determining the final steps.

Diacetyl Rest and Off-Flavor Prevention

Wyeast 1187 Ringwood Ale benefits from a deliberate Ringwood diacetyl rest after active fermentation. Raise the beer to the upper end of the strain’s temperature range, about 70–74°F (21–23°C), for 24–48 hours when gravity nears terminal. This step helps yeast reabsorb diacetyl and reduces the risk of buttery flavors.

Effective off-flavor control begins before fermentation. Use healthy, active yeast and pitch an appropriate starter or multiple packs to assure strong fermentation. A robust yeast population shortens the window for diacetyl formation and improves cleanup during the rest.

Monitor fermentation progress with gravity readings rather than a clock. When activity slows and gravity is close to final, begin the diacetyl rest. Keep the beer aeration minimal during this time to avoid oxidation and let the yeast finish reducing precursors to harmless compounds.

After the diacetyl rest, allow time for conditioning so yeast can settle and any remaining off flavors mellow. If needed, extend contact with yeast by leaving the beer on the trub a little longer to enhance off-flavor control and clarity.

- Raise temperature to 70–74°F (21–23°C) for 24–48 hours when fermentation slows.

- Ensure proper pitch rate and yeast health to prevent diacetyl formation.

- Use gravity readings to time the rest, then condition to allow cleanup.

Best Beer Styles to Brew with This Yeast

Wyeast 1187 Ringwood excels in classic English ales. It's perfect for Pale Ales and Bitters, bringing out gentle fruit esters and mild malt sweetness. These are key characteristics for these styles.

Porters and Brown Ales benefit from Ringwood's nutty and toffee notes. A malty grain bill, including crystal and brown malts, enhances these flavors. This combination is ideal for showcasing the yeast's strengths.

Stouts, particularly American Stout or Oatmeal Stout, are well-suited for this yeast. It supports roasty and chocolate malts, preserving the beer's mouthfeel. This makes it a top choice for those seeking malt complexity.

Ringwood also works well with hop-forward beers. For an American IPA, ferment on the warmer side. This brings out brighter fruit esters that complement the hops.

Fruit beers also respond well to this strain. Light, sweet fruit additions allow the fruit to take center stage. Meanwhile, Ringwood adds a subtle backbone to the beer.

- Pale Ale and Bitter — classic English expression

- Brown Ale and Southern English Brown — malty, nutty focus

- Porter and Oatmeal Stout — robust malt complexity

- American IPA — ester lift for hop brightness

- Fruit Beer — supports fruit adjuncts without overpowering

Choose recipes based on your desired outcome. Use richer malts for nutty/toffee character. For a cleaner hop showcase, ferment cooler and control temperature.

Ringwood offers versatility in brewing. Its balance between malt depth and ester-driven brightness makes it a reliable choice. It suits both traditional and modern recipes.

Recipe Considerations and Formulation Tips

Decide on the body you desire for your beer. The grain bill should reflect this choice. For a fuller mouthfeel, increase mash temperature slightly and include 10–20% medium crystal malts. Conversely, for a drier finish, lower mash temperature and use well-modified base malts like Maris Otter or US two-row.

Consider the fermentability of your malts. Use highly modified malts to enhance attenuation for a leaner profile. To preserve sweetness and roundness, incorporate dextrin malts or oats and maintain higher mash temperatures. These adjustments lead to predictable changes in residual sugars and perceived body.

When selecting hops for Ringwood, align them with the yeast's fruity esters. Hops like Citra or Cascade complement the yeast's orange and stone-fruit notes. Balance bitterness by pairing these hops with moderate late additions and dry hopping to avoid harsh bitterness that masks esters.

Match specialty malts to your style goals. Brown malts and crystal sugars enhance toffee and nutty tones in English bitters and brown ales. Oats and flaked barley add silkiness to stouts. Use modest adjuncts to keep the yeast character central.

- For English bitters: 70–80% Maris Otter, 10% crystal 40–80L, 5% brown malt.

- For American pale ales: 90% two-row, 5% crystal 20L, 5% dextrin malt; hop pairing with Ringwood: Citra or Cascade.

- For robust stouts: 65% pale malt, 15% roasted barley, 10% flaked oats, 10% crystal.

Adjust bitterness to highlight esters. Keep IBUs moderate for malt-forward ales and increase them for hop-driven styles. When crafting a grain bill for Ringwood, balance crystal content and roast character to avoid clashing with the yeast's fruitiness.

Control mash and fermentation to achieve target attenuation. If measured attenuation lags, extend primary fermentation or raise temperature by a few degrees late in fermentation. If beer finishes too dry, raise mash temperature or increase dextrin malt in future batches.

Keep records of mash temperatures, percent specialty malts, and hop pairing with Ringwood for each batch. Small tweaks lead to consistent improvements over time. Use these Ringwood recipe tips to refine body, ester balance, and hop interplay in your next brew.

Pitching Rates, Starter Recommendations, and Yeast Health

Wyeast 1187 Ringwood exhibits a slow start. For most ales, aim for a pitching rate of 0.75 to 1.5 million cells per milliliter per degree Plato. For higher gravity beers, increase the Ringwood pitching rate to reduce lag and stress on the yeast culture.

Building a yeast starter is crucial for stronger or complex recipes. A starter sized to the batch gravity will speed up fermentation and ensure clean attenuation. For 5-gallon ales above 1.060, consider a two- to three-liter starter or a step-up build to achieve the necessary cell count.

To protect yeast vitality, oxygenate the wort before pitching and maintain fermentation temperatures within the recommended range. Use a measured dose of yeast nutrient for high adjunct percentages or low oxygen conditions to prevent stalled fermentations.

If a starter shows slow growth, try a gentle warm rest and swirl to resuspend the yeast before adding it to the batch. A healthy yeast starter for Ringwood should have a clean smell, with no solvent or putrid notes. It should also have a thick, creamy krausen when active.

- Pitch larger for near-tolerance gravities to maintain yeast vitality and reduce off-flavor risk.

- Oxygenate wort to about 8–12 ppm for ales to support early cell growth.

- Use staggered nutrient additions for very high gravity worts to limit stress on Ringwood.

Monitor gravity rather than relying solely on visual activity. Ringwood can ferment steadily while showing modest headspace activity. Accurate gravity checks tell you if the pitch rate and starter did their job and if yeast vitality remains strong.

Conditioning, Cold Crashing, and Packaging

Extended Ringwood conditioning allows flavors to meld and harsh esters to settle. Aim for at least three weeks of fermentation and conditioning. Many brewers note improved clarity and a rounder mouthfeel after this period.

Implement a gentle cold crash Ringwood protocol to enhance clarity. Lower the temperature to near-freezing for about 48 hours. This duration aids in yeast and trub settling without shocking the beer.

Following the cold crash, allow the fermenter to warm to room temperature the next day. This brief pause minimizes the risk of stirring up settled yeast when racking or transferring.

Consider the packaging implications of high-floc yeast. High flocculation means fewer yeast cells in suspension at packaging. However, it's crucial to leave sediment behind in the fermenter. Racking carefully prevents excess sediment from entering bottles or kegs.

Avoid stirring the yeast before packaging. Opt for gentle siphoning and minimize splashing to achieve clearer beer and lower diacetyl risk. If additional yeast is needed for bottle conditioning, add a small, healthy starter instead of disturbing settled yeast.

Stick to standard carbonation practices when bottling or kegging. Consider the residual gravity when calculating priming sugar to achieve your desired CO2 levels. For draft systems, carbonate to style-appropriate levels using a CO2 tank or set keg pressure.

- Typical conditioning timeline: 3+ weeks total.

- Cold crash Ringwood: ~48 hours near 32–40°F.

- Packaging with high-floc yeast: rack gently, leave sediment behind.

Common Issues and Troubleshooting

Slow starts are common with ale yeasts, including Wyeast 1187. To fix slow fermentation, start with a larger starter to increase cell count. Ensure dissolved oxygen is adequate at pitching and maintain the recommended wort temperature to reduce lag time.

If esters seem muted, give the beer more time. Extend active fermentation and conditioning to three to four weeks. This allows the yeast to finish fermentation and develop aromatic esters.

- Pitch at recommended rates to avoid stressed yeast.

- Use a stir plate or healthy starter for higher viability.

- Maintain steady temperatures to support yeast activity.

Buttery or diacetyl notes can appear in clean ales. For diacetyl troubleshooting, raise the temperature to the upper end of the yeast range, about 70–74°F (21–23°C). Hold for 24–48 hours to let yeast reabsorb diacetyl.

Clarity problems are rare with high-flocculation strains but can persist if conditioning is rushed. Cold crash for several days and allow extended conditioning before packaging. Gently rouse the yeast if you plan to bottle before a full settling period.

- If fermentation stalls, measure gravity and warm the fermenter slightly.

- For persistent diacetyl, give more time at rest and avoid oxygen exposure during transfer.

- When haze remains, increase cold conditioning and consider fining agents if clarity is critical.

Use this Ringwood troubleshooting checklist as a practical guide. Address pitching, oxygenation, temperature control, and time first. These steps cover most slow fermentation fixes and diacetyl troubleshooting scenarios brewers face in home and pro setups.

Comparisons to Other Ale Yeasts

Ringwood yeast stands out for its fruity esters and nutty, toffee-like flavors. When you taste a beer made with Wyeast 1187, you'll notice a unique character. This is something many neutral yeasts can't offer.

US-05 and Nottingham yeasts, on the other hand, provide cleaner, more neutral results. Brewers often choose US-05 for hop-forward beers. They want the malt and hops to shine without yeast-derived fruitiness.

Fermentation kinetics between Ringwood and other ale yeasts are quite different. Ringwood ferments more slowly, requiring a longer primary fermentation time. You'll need to plan for extra time to reach terminal gravity and to clear before packaging.

Flocculation is another key difference. Wyeast 1187 comparison often shows higher flocculation compared to low-flocculating strains. This trait makes Ringwood better for achieving clarity without the need for extended cold conditioning.

- Flavor contrast: Ringwood brings estery complexity and malt complement that many neutral strains lack.

- Timing: slower fermentation means adjusting schedules for full attenuation.

- Clarity: higher flocculation aids natural clearing compared with yeasts that stay hazy longer.

When deciding between Ringwood and other ale yeasts, consider your beer's goals. Choose Wyeast 1187 for malt-driven, estery ales. For hop-centric pale ales and IPAs, opt for cleaner strains. This way, yeast won't compete with hop aromatics.

Understanding ale yeast profiles is crucial for brewers. Study how Wyeast 1187 comparison parameters affect aroma, mouthfeel, and conditioning needs. This knowledge will help you make informed decisions before starting a recipe.

Real-World Brewing Notes and User Experiences

Homebrewers often share similar timelines when using Wyeast 1187. They note that fermentation seems slow after the first week. However, patience is rewarded; many suggest planning for three weeks or more for full flavor.

Wyeast 1187 brewer notes from the community highlight flavor evolution over time. One brewer noted grapefruit-like notes at three weeks, absent at two. This change illustrates how esters and malt character evolve during conditioning.

Practical workflows are straightforward and consistent. Most brewers extend primary fermentation, then cold crash for 48 hours to enhance clarity. Afterward, allow the beer to warm to room temperature before packaging for better carbonation and mouthfeel.

Recipe outcomes demonstrate the yeast's versatility. Ringwood user experiences span over two thousand recipes, from pale ale to stout. Many praise the balance of fruity esters and malty complexity Wyeast 1187 produces, regardless of grain bill or hopping rate.

Community consensus values the yeast's natural clarification and distinct profile. Ringwood fermentation stories frequently emphasize the importance of patience and proper yeast management. This leads to cleaner flavors and better stability. Consistent pitching rates and healthy starters help minimize variability.

For practical tips, try these steps:

- Pitch a healthy starter to match gravity and batch size.

- Keep fermentation temperatures steady within the recommended range.

- Wait at least three weeks before judging final character.

- Cold crash for 48 hours, then warm before packaging.

These Wyeast 1187 brewer notes reflect hands-on experience rather than theory. Brewers who adopt a steady, patient approach tend to achieve the most consistent and satisfying results with this strain.

Conclusion

Wyeast 1187 summary: This Ringwood ale strain offers fruity esters, nutty, toffee-like malt character, and high flocculation. It has moderate attenuation around 70% and can tolerate up to 10% ABV. This makes it versatile for many English-style and robust ales. It excels when allowed to express gentle esters without harsh phenolics.

Best practices for Ringwood include pitching a healthy starter and fermenting between 64–74°F (18–23°C). Plan for a longer timeline of 3–4 weeks for total fermentation and conditioning. A diacetyl rest is crucial to clean up buttery off-flavors. Cold crashing and extended cold conditioning enhance clarity due to the yeast’s strong flocculation.

Wyeast 1187 is ideal for brown ales, porters, stouts, and hop-forward ales where fruity esters complement malt and hops. Adjust the mash profile and recipe formulation to balance body and attenuation for your desired style. With proper yeast health management and patience, Wyeast 1187 yields a clean appearance and the characteristic flavors brewers seek.

Further Reading

If you enjoyed this post, you may also like these suggestions:

- Fermenting Beer with Fermentis SafAle BE-134 Yeast

- Fermenting Beer with Fermentis SafAle S-33 Yeast

- Fermenting Beer with White Labs WLP300 Hefeweizen Ale Yeast