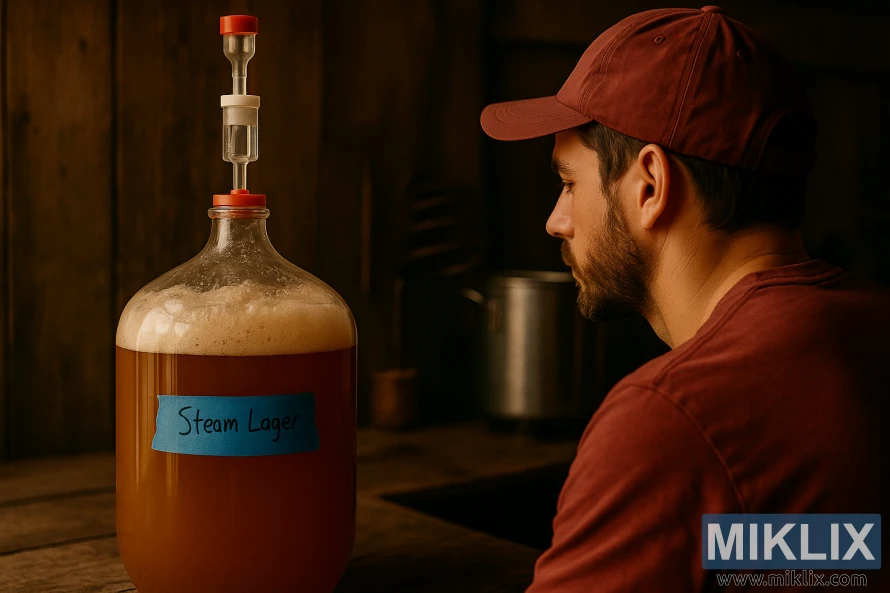

Fermenting Beer with Bulldog B23 Steam Lager Yeast

Published: October 28, 2025 at 11:00:21 PM UTC

Bulldog B23 Steam Lager Yeast is a dry lager yeast designed by Bulldog Brewing. It's perfect for brewers aiming for clean, crisp lagers with minimal fuss. This introduction highlights the yeast's identity, performance, and who it's best for. It's ideal for those new to homebrewing steam lagers and traditional lagers.

The yeast is sold in a single dry sachet, usually priced around £2.50 per pack. It has an attenuation rate of 75–78%, depending on the source. Flocculation notes vary, influenced by the recipe and yeast profile. For classic lagers, it thrives at 13–20°C. For California common or steam lagers, it can handle temperatures up to 25°C.

This guide is geared towards U.S. homebrewers, including novices. It focuses on a dry lager yeast that's forgiving. The following sections will dive into pitch rates, temperature control, fermentation timeline, and recipe ideas. This will help you determine if Bulldog B23 is right for your next brew.

Key Takeaways

- Bulldog B23 Steam Lager Yeast is a dry lager yeast for clean, crisp lagers and steam styles.

- Typical attenuation is around 75–78%, with mixed notes on flocculation to explore later.

- Packaged as a single sachet, often priced around £2.50 in recipe references.

- Use 13–20°C for traditional lagers; 18–25°C can suit steam lager or California common.

- Well suited to homebrewers who want an easy-to-manage lager strain.

Overview of Bulldog B23 Steam Lager Yeast

The Bulldog B23 overview starts with a clear description: it's a dry lager yeast marketed as Steam Lager (B23). The manufacturer suggests fermenting between 13–20°C, with 78% attenuation and high flocculation. This indicates a reliable yeast for cool lagers.

Brewer reports provide an alternative B23 strain profile. One recipe entry shows it as dry, with custom attenuation near 75%. It has low flocculation and an optimal temperature range of 18–25°C. This data highlights B23's adaptability to warmer "steam" or California common fermentations.

Practical traits of the steam lager yeast profile include high attenuation and a dry finish. Expect final gravities that result in crisp, drinkable beers. These characteristics make it ideal for both traditional lagers and hybrid styles, where a clean base enhances malt and hop flavors.

It's suitable for German-style lagers and California common beers. Homebrewers value B23 for its predictable attenuation and consistent fermentation in single-sachet packs. These packs are often priced around £2.50 each in retail listings.

When planning a recipe, consider the B23 strain profile and your temperature control. Ferment at the lower end for a lager-like cleanliness or the higher end for steam-style ester development. This flexibility is the main appeal of Bulldog B23 to many hobbyists and small commercial brewers.

Why Choose Bulldog B23 Steam Lager Yeast for Homebrewing

Homebrewers often wonder why they should choose B23 for steam lager. The answer is simple: it's easy to use. The dry format of Bulldog B23 is convenient, as it stores well and eliminates the need for starters. This makes it perfect for beginners, who appreciate the straightforward pitching process.

The flavor profile of B23 is versatile, fitting various beer styles. It offers a clean, crisp finish, ideal for German lagers and California Common beers. Brewers looking for the best yeast for steam lager will find its neutral ester production and ability to enhance malt and hop flavors appealing.

- Consistent attenuation around 75–78% yields predictable final gravities.

- Medium alcohol tolerance matches typical lager ABV ranges without stressing the yeast.

- Dry sachet format lowers per-batch cost, making Bulldog B23 benefits attractive for regular brewing.

B23's versatility makes it a top choice in homebrew lager yeast selection. It works well with pilsner and lager malts, as well as in California Common recipes. This flexibility allows brewers to experiment while ensuring reliable fermentation.

When evaluating strains, consider metrics like attenuation, tolerance, and cost. For many brewers, B23's balance of predictable results and economy makes it a preferred lager strain.

Preparing Your Wort for Steam Lager Fermentation

Begin by crafting a grain bill that mirrors a California Common. Use Extra Pale Ale and Pilsner/Lager malts as the foundation. Incorporate Munich Type I and small specialty malts like amber or chocolate to enhance color and depth. Rice hulls may be necessary to support your lautering system.

Conduct an infusion mash at 65 °C (149 °F) for 60 minutes. Maintain a mash thickness of about 3 L/kg to optimize enzyme activity. Run a sparge at 72 °C (162 °F) for 20 minutes. These steps are crucial for controlling fermentability and body.

Ensure the mash pH for steam lager is correct early on. Aim for a pH of roughly 5.4 at mash temperature. Use phosphoric acid or food-grade lactic acid to adjust pH levels. Gypsum or calcium salts may be needed to fine-tune sparge chemistry.

Choose a water profile that complements your recipe for steam lager. A balanced profile should include higher calcium, moderate chloride, and sulfate. This enhances mash performance and hop character. Avoid extreme bicarbonate levels for a clean profile.

Plan your hops and bitterness according to the style. Opt for Fuggle and Challenger or similar varieties to achieve 30–35 IBU. Use kettle and whirlpool additions. Ensure hop choices align with the malt backbone and desired steam lager aroma.

Focus on wort conditioning before pitching. Cool the wort quickly to the desired temperature. Then, oxygenate to support yeast growth. Proper conditioning will enhance attenuation and help high-attenuation strains like Bulldog B23 reach their full potential.

Measure the original gravity and adjust as needed to match your target. Consider the fermentability of adjuncts when calculating expected gravity and oxygen needs. Small changes in gravity significantly impact yeast performance and the beer's final balance.

Utilize a checklist: mash schedule, mash pH for steam lager, water profile for steam lager, hop schedule, cooling and oxygenation, and final wort conditioning. Adhering to this order minimizes surprises at pitching and ensures a healthy fermentation for the Bulldog B23 yeast.

Pitching Rates and Yeast Handling

Accurate Bulldog B23 pitching rates are crucial for consistent fermentation. Many steam lager recipes aim for around 0.35 million cells per ml per °P. For a 20-liter batch with moderate gravity, this translates to nearly 96 billion cells.

Proper dry yeast handling is essential for maintaining viable cell counts. Brewers often follow manufacturer guidelines for yeast rehydration B23. This involves using warm, sanitized water and a gentle rest before pitching. Some producers allow direct sprinkling into wort when temperatures match, but thermal shock must be avoided.

Even without a starter, you can assess the risk based on batch gravity and volume. For higher original gravities or large batches, consider a starter or add extra sachets. A pitch rate calculator can help determine the required cells and sachet counts based on gravity and volume.

Practical steps for safe dry yeast handling:

- Sanitize all utensils and the rehydration vessel.

- Use water at the manufacturer’s recommended temperature for yeast rehydration B23.

- Match the temperature of rehydrated yeast to wort to avoid shock.

- Consider multiple sachets instead of a starter when time is limited.

Dry sachet yeast offers a long shelf life and is cost-effective. Stored cool and dry, it retains viability longer than liquid yeast. The typical retail pricing is budget-friendly, making it economical to add a second sachet for the Bulldog B23 pitching rate, rather than risking a failed ferment.

Before brewing, use a pitch rate calculator. Input batch volume and gravity, then check the recommended cell counts. Compare these with sachet yields. Adjust for the sachet's age and storage history when planning yeast additions.

Fermentation Temperatures and Management

Bulldog recommends a B23 fermentation temperature range of 13.0–20.0°C. This range suits both classic lagers and more expressive steam lagers. The cooler end is ideal for lagers, while the warmer end enhances steam lager characteristics.

For a clean, lager-style profile, start fermentation at 13–15°C. Maintain a steady temperature and include a diacetyl rest before cold conditioning. This method helps preserve the crisp malt character and minimizes esters.

For a California Common or steam lager, aim warmer. A steam lager temperature range of 18–22°C promotes attenuation and the subtle fruity esters characteristic of the style. Many brewers achieve good results fermenting B23 at 18–25°C for this flavor profile.

To manage fermentation temperature, monitor both tank temperature and specific gravity. Track gravity daily until it stabilizes. Consistent thermal control prevents stuck fermentations and reduces off-flavor risk.

- Use a temperature-controlled chamber for precise regulation.

- Employ a swamp cooler with frozen bottles for small batches when tight control is unnecessary.

- Place the fermenter in a stable room and insulate to avoid swings for basic setups.

Check pH and gravity alongside temperature to evaluate progress. The choice between lager vs steam fermentation depends on the target flavor and attenuation. Match your temperature strategy to the beer you aim to create.

Fermentation Timeline and Monitoring

Plan the B23 fermentation timeline around active primary fermentation, which often finishes in several days to two weeks. With expected attenuation near 75–78%, Bulldog B23 moves quickly through early fermentation stages. This is when pitched at the right rate and kept in the recommended temperature range.

Keep a routine for fermentation monitoring to catch issues early. Log temperature daily, check krausen and activity, and record specific gravity readings. Consistent notes make it easier to compare batches and to spot stalled or slow fermentations.

- Track gravity readings Bulldog B23 from the first 24–48 hours, then every 24–72 hours until stable.

- Measure pH and observe krausen height to confirm healthy yeast activity.

- Note temperature swings and correct them promptly to protect ester profile and attenuation.

An example California Common with OG 1.053 and FG 1.012 reached expected endpoints and about 5.4% ABV. This shows typical performance for moderate-strength beers. Use gravity readings Bulldog B23 to time transfers and conditioning steps rather than relying on fixed days alone.

Allow time for diacetyl cleanup if fermenting on the cool side. A short diacetyl rest near the end of active fermentation helps yeast reabsorb off-flavors. Taste and measure specific gravity to decide when to start lagering or secondary conditioning.

Follow the fermentation stages from lag to high activity, slowdown, and final conditioning. Good fermentation monitoring and steady conditions help Bulldog B23 complete attenuation. This ensures the clarity and flavor profile your recipe aims for.

Flocculation and Clarification Considerations

Bulldog B23 often exhibits strong settling in lab tests, but real-world results vary. Generally, expect good B23 flocculation. Yet, wort composition, fermentation temperature, and yeast health significantly influence outcomes.

Some homebrewers face yeast flocculation challenges with dry strains. They might see loose trub or light sediment in bottles. This doesn't always signify yeast failure. It could be due to specific batch conditions, mash profiles, or handling during transfer.

To enhance clarity, employ practical clarification methods. Cold crash and fining are effective for most ales and steam-style lagers.

- Cold crash: drop to near-freezing for 24–72 hours to encourage particles to settle.

- Finings: Whirlfloc in the boil or gelatin in conditioning target haze-forming proteins and yeast.

- Extended lagering: longer cold conditioning promotes compact sediment without aggressive handling.

When bottling, it's crucial to leave sediment behind. Rack into a bottling bucket slowly and avoid disturbing the trub to limit sediment transfer into bottles.

If bottle sediment remains a concern, try a secondary settling period or longer cold conditioning before priming. Filtration or pre-packaging finings can be used if equipment and style goals allow.

Track outcomes across batches. Note how mash pH, hop levels, and fermentation temperature affected clarifying Bulldog B23. Small adjustments help resolve intermittent yeast flocculation issues and produce clearer beer with consistent results.

Alcohol Tolerance and Style Limits

Bulldog B23 exhibits a medium alcohol tolerance, ideal for session and moderate-strength lagers. Brewers find steady fermentations and clean profiles within the typical B23 alcohol tolerance range. This makes it a reliable choice for brewing.

For instance, a brew reached 5.39% ABV from an original gravity of 1.053 and a final gravity of 1.012. This outcome aligns with the ABV limits Steam Lager yeast can achieve without special handling.

When planning recipes, keep these points about Bulldog B23 limits in mind:

- Target session or mid-single-digit ABV beers for reliable attenuation.

- Use extra pitching rates, oxygenation, and nutrients if pushing beyond the usual Bulldog B23 limits.

- Expect best performance in clean-attenuating lagers and California common styles.

Recommended brewable styles B23 include traditional German lagers, steam/California common, and other restrained lagers. These styles benefit from a crisp finish. Avoid relying on this strain for very high ABV designs unless you plan cell-count boosting or step-feeding.

When formulating recipes, balance fermentability and mouthfeel to match the ABV limits Steam Lager yeast will realistically achieve. Managing mash profile, oxygen, and nutrients keeps Bulldog B23 limits predictable and repeatable.

Common Recipes and Recipe Examples Using Bulldog B23

Bulldog B23 recipes range from crisp pilsners to warmer steam beers. Brewers showcase its versatility in various styles, proving it's a go-to choice in real brewing environments.

The "Tiggy’s Tipple" by Brewer’s Friend is a standout Bulldog B23 recipe. This California Common recipe is for a 21 L batch, with an OG of 1.053 and FG of 1.012. It yields about 5.4% ABV. The grain bill combines Extra Pale Ale and Pilsner malts, along with Munich and specialty malts. Mash rests at 65 °C for 60 minutes.

In the Tiggy’s Tipple recipe, British hops like Fuggles and Challenger are used for balanced bitterness around 33 IBU. The water and mash treatment include Balanced Profile II, gypsum, and phosphoric acid to adjust pH. Whirlfloc is added at the boil to enhance clarity.

For Bulldog B23, recipes can range from traditional lagers to steam lagers. Steam lagers often use hybrid mash profiles and dry pitching rates for clean esters and a firm finish.

Practical tips from the California Common recipe B23 and similar examples include maintaining consistent mash temperatures. Add finings like Whirlfloc only at the boil. Consider using rice hulls to prevent stuck mashes with high adjunct bills. Dry pitching at recommended rates simplifies preparation for homebrewers.

- Example mash: 65 °C for 60 min for malt balance.

- Typical hops: Fuggles, Challenger or other English varieties for subtle bitterness.

- Finings: Whirlfloc at boil for clearer beer.

- Water: adjust with gypsum and phosphoric acid to control profile and pH.

Homebrewers looking for a Bulldog B23 recipe will find it adaptable. Lower temperatures lead to lager clarity. Higher temperatures result in a true steam character, ideal for California Common-style beers.

Troubleshooting Common Issues with Bulldog B23

Begin by examining the fermentation temperature. Fermenting too warm can introduce unwanted esters. On the other hand, fermenting too cool can slow down the process and lead to stuck fermentation B23. It's crucial to match the temperature to your target style, whether it's cooler for lagers or warmer for steam or California common beers.

Be on the lookout for off-flavors from B23 that could indicate temperature fluctuations or oxygen issues. Diacetyl, solvent notes, or harsh esters often signal yeast stress. To address this, gently raise the temperature for a diacetyl rest when gravity stalls. Give the beer ample time to clear.

Don't overlook the issue of underpitching. Low cell counts can result in sluggish starts and various Bulldog B23 problems. Use a pitch calculator, create a starter for high-gravity beers, or add a second sachet to ensure proper cell counts.

Oxygenation and nutrients are also critical. Poor aeration at pitch and insufficient FAN (free amino nitrogen) can cause stuck fermentation B23. If the beer is early in fermentation, reoxygenate carefully. Consider adding yeast nutrient for high-gravity or low-nutrient worts.

- Loose sediment or low flocculation: cold-conditioning and cold crashing improve clarity.

- Fining agents such as gelatin or Whirlfloc help compact yeast before packaging.

- Longer conditioning in the fermenter reduces yeast in bottles and improves shelf stability.

Monitor gravity trends, not just a single reading. A stalled gravity that does not change over several days signals the need for intervention. Gentle warming and nutrient additions can coax fermentation to finish. If gravity remains unchanged, consider repitching a healthy, active yeast strain.

Reconcile inconsistent flocculation reports by adjusting process variables. Changes in wort composition, mash profile, and temperature can alter yeast behavior. If a recipe reports heavy yeast in bottles, plan to extend conditioning and use clarification steps.

- Check temperature profile first.

- Confirm pitch rate and oxygenation.

- Allow time for natural diacetyl rest before aggressive fixes.

- Use clarification techniques to address sediment and appearance issues.

Keep detailed notes on each batch to identify recurring Bulldog B23 problems. A comprehensive log of temperatures, pitch rates, and gravity curves will streamline troubleshooting B23 for future brews.

Comparing Bulldog B23 to Other Dry Lager and Ale Strains

Homebrewers seeking a clean, crisp finish often turn to the Bulldog B23. It stands out in the Bulldog B23 comparison with other strains due to its lager-like behavior. B23 typically achieves higher attenuation, around 75–78%, resulting in a drier beer than many ales.

When evaluating steam lager yeast options, temperature range and ester production are key. Bulldog B23 excels in warmer fermentation temperatures, ideal for California Common styles. It also keeps esters low, making it a top choice for those desiring steam lager character without the fruitiness of English or American ales.

Flocculation significantly impacts mouthfeel and clarity. Bulldog B23 boasts high flocculation, leading to better sediment compaction and clearer beers. Other dry strains may have loose lees or lower flocculation, affecting performance from batch to batch.

Choosing between dry ale and dry lager strains is a matter of flavor preference. Ale strains produce more esters and character, perfect for pale ales and English styles. B23, on the other hand, offers a neutral, crisp finish, ideal for lagers and hybrid styles where malt and hops should dominate.

- Performance: B23 offers reliable attenuation and consistent fermentation kinetics.

- Versatility: Use B23 for true lagers, steam lagers, and California Common approaches.

- Clarity: High flocculation often speeds conditioning and brightening.

- Flavor: Choose ale strains when ester complexity is desired.

When deciding, align yeast traits with your recipe goals. For a clean lager character or to compare steam lager yeast candidates for warm-fermenting lagers, Bulldog B23 is a strong contender. For fruity esters and a different sediment profile, opt for a known ale strain.

Packaging, Conditioning, and Serving Tips

When packaging Bulldog B23, it's crucial to keep trub out of the final beer. Start by racking clear beer from the fermenter into a bottling bucket or keg. Leave the sediment behind. Use a bottling wand to fill bottles slowly, minimizing oxygen pickup and preventing excess sediment.

For priming Bulldog B23, calculate the sugar precisely. A common example uses 112.4 g sucrose for 21 L to achieve about 2.2 volumes of CO2. Adjust this amount as needed to match your desired carbonation level for the style.

Consider kegging for clearer pours and easier control. Kegging allows for force-carbonating and avoids the variability of bottle conditioning. If bottles are your preference, pour gently and store them upright for several days to allow yeast to settle.

Extended cold conditioning is key for conditioning steam lager. After a cold crash, move the beer to a lagering fridge for several weeks. This process clarifies and compacts the sediment. Use finings like Whirlfloc in the boil or gelatin pre-packaging to enhance clarity when flocculation is inconsistent.

- Short cold crash: 24–72 hours to drop out haze.

- Extended lagering: 2–6 weeks for clearer beer and smoother flavor.

- Fining options: Whirlfloc in the boil or gelatin in secondary for extra polish.

Temperature is crucial when serving steam lager. Traditional lagers are best served very cold after proper lagering. California common or steam styles, on the other hand, retain more aroma when served slightly warmer. Match the carbonation to the style: tighter carbonation for crisp lagers, a touch lower for a rounded steam lager experience.

Lastly, monitor clarity and taste before packaging. If the beer tastes young or yeasty, give it more time on cold. Proper conditioning enhances stability, mouthfeel, and shelf life for both bottled and kegged beer.

Conclusion

Bulldog B23 conclusion: This dry lager yeast is a reliable, versatile choice for U.S. homebrewers. It offers high attenuation, around 75–78%, and a clean, crisp finish. It's also flexible, suitable for both cool lagers and warmer steam/California common styles. For everyday recipes, it's dependable and easy to use in dry form.

When brewing with B23, you can expect several benefits. It's cost-effective, easy to pitch, and tolerates a wide temperature range. These traits make it ideal for Belgian-tinged lagers, classic steam beers, and sessionable pilsners. The yeast's practical reliability across many styles is a major plus.

There are, though, some caveats. Reports vary on flocculation, and it has a medium alcohol tolerance. For crystal-clear beer, you'll need to cold crash or use finings. Also, be cautious with very high-ABV batches. These minor drawbacks are worth it for the convenience and consistency of Bulldog B23.

Bulldog B23 final thoughts: For homebrewers looking for an affordable, predictable dry lager yeast, this is a great choice. Just remember to follow proper pitching rates, maintain good temperature control, and clarify your beer for the best results.

Further Reading

If you enjoyed this post, you may also like these suggestions:

- Fermenting Beer with Fermentis SafAle WB-06 Yeast

- Fermenting Beer with Fermentis SafSour LP 652 Bacteria

- Fermenting Beer with Mangrove Jack's M21 Belgian Wit Yeast