Fermenting Beer with White Labs WLP925 High Pressure Lager Yeast

Published: December 26, 2025 at 10:19:52 AM UTC

White Labs WLP925 High Pressure Lager Yeast is a key strain in the White Labs yeast collection. It's designed to speed up lager fermentation while maintaining clean lager characteristics. This yeast is a top choice for brewers aiming for a quick transition from wort to final gravity.

Under the recommended conditions, WLP925 can hit final gravity in about a week. This is achieved by fermenting at room temperature and applying pressure. The typical fermentation program involves fermenting at 62–68°F (17–20°C) under up to 1.0 bar (14.7 PSI) until final gravity is reached. Then, conditioning at 35°F (2°C) with 15 PSI for a few days is recommended.

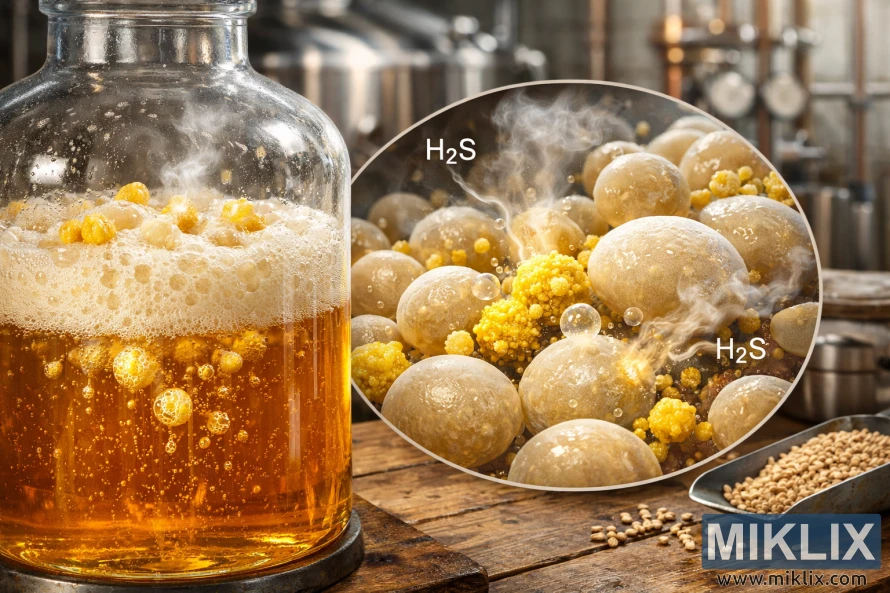

WLP925 boasts 73–82% attenuation, medium flocculation, and can handle alcohol up to 10%. However, brewers should be aware of a notable sulfur (H2S) spike in the first two days. This usually clears by day five.

This WLP925 review aims to provide practical insights on its behavior and style suitability. White Labs suggests using WLP925 for a variety of lagers, from pale to darker. This introduction prepares you for the upcoming sections on high-pressure fermentation techniques and troubleshooting.

Key Takeaways

- White Labs WLP925 High Pressure Lager Yeast is designed for fast, clean lager ferments.

- Recommended fermentation: 62–68°F (17–20°C) under up to 1.0 bar, then lager at 35°F (2°C).

- Typical attenuation 73–82% with medium flocculation and 5–10% alcohol tolerance.

- Expect an H2S peak in the first two days that generally dissipates by day five.

- Well suited to styles like Pilsner, Helles, Märzen, Vienna Lager, and American Lager.

Why Choose White Labs WLP925 High Pressure Lager Yeast for Your Lager

White Labs WLP925 is a top choice for brewers seeking fast, reliable results. It's ideal for those who value speed and purity. Engineered for high-pressure performance, it offers significant advantages for both craft breweries and homebrewers.

Its standout feature is quick lager fermentation. Under optimal conditions, White Labs notes final gravity is often achieved in just one week. This strain's benefits include reduced yeast growth and lower metabolite production. These factors help maintain a clean, crisp lager taste, even when fermenting at warmer temperatures than usual.

WLP925 is known for its neutral flavor, making it perfect for classic lager styles. It's suitable for Pilsner, Helles, Märzen, Vienna, Schwarzbier, amber lagers, and modern American lagers. The result is ultra-drinkable beers with minimal ester and off-flavor formation, provided it's managed correctly.

Its flexibility is another key advantage. It performs well with both warm-pitch, high-pressure fast-lager techniques and traditional cold-lager schedules. This makes it an excellent choice when brewery capacity or turnaround time is tight. It allows for faster batch cycles without compromising on lager character.

- Practical fit: broad style range from pale Pilsners to darker lagers.

- Operational advantage: shorter fermentation windows that free tank time.

- Clean profile: minimal esters for classic lager clarity.

- Limits: medium alcohol tolerance around 5–10% and STA1 negative behavior.

When planning recipes, certain considerations are crucial. STA1 negative means no dextrinase activity, so expect typical attenuation for the wort gravity used. The medium alcohol tolerance limits very high gravity lagers. Adjust grain bills or consider step-feeding for stronger brews.

In summary, if you're looking for quick lager fermentation without compromising on taste, WLP925 is a compelling choice. Its benefits and high pressure lager yeast advantages make it ideal for modern lager production.

Understanding High Pressure Fermentation and Its Effects on Flavor

Positive pressure during fermentation reduces yeast growth and metabolic activity. This change often leads to lower ester formation and fewer fermentation byproducts. Brewers use this to control aroma without dropping temperature.

White Labs designed WLP925 pressure fermentation for this purpose. The strain tolerates up to 1.0 bar (14.7 PSI) so you can push FG quickly. Under these conditions, many brewers see finished gravity in about one week.

Practical spunding valve flavor impact shows up when you ferment warmer but under pressure. You get cleaner profiles at higher temperatures compared to open fermentation. Brewers often target modest spunding values to limit ester rise while preserving fermentation speed.

- Common homebrew targets run 5–8 PSI for a balance of speed and cleanliness.

- Some community trials go to 12 PSI, but that can slow CO2 release and alter mouthfeel.

- White Labs guidance stays conservative, under 1.0 bar, to avoid stress on yeast.

Pressure and ester suppression is central to why many choose pressurized ferments. With less yeast growth comes reduced in-ferment complexity. That trade-off suits lagers where a clean malt and hop expression matter more than estery character.

Pressure can also change diacetyl dynamics. Reduced yeast activity may slow diacetyl reduction, so monitoring gravity and planning diacetyl rests remains essential. A short warm rest near the end helps the yeast finish cleanup before lagering.

Expect slower clearing when you ferment under pressure. CO2 retention and limited flocculation under pressure can delay brightening. Brewers often rely on flocculation-friendly strains, careful cold conditioning, or extended clarification time to reach the desired clarity.

For applied practice, try these steps:

- Pitch healthy yeast and set a conservative spunding valve around 5–8 PSI.

- Track gravity daily and watch for a steady drop toward FG.

- Plan a diacetyl rest if gravity stalls or if the beer shows buttery notes.

- Cold-condition longer if clarity is slow due to retained CO2.

WLP925 pressure fermentation gives a tool for faster lagers with clean profiles. Use modest pressure, monitor the beer, and weigh the trade-offs between ester suppression and in-ferment complexity to achieve the flavor you want.

Fermentation Parameters: Temperature, Pressure, and Time

For primary fermentation under pressure, set the WLP925 fermentation temperature between 62–68°F (17–20°C). This range promotes clean ester profiles and quick progress toward final gravity.

Target pressure settings WLP925 at or below 1.0 bar (14.7 PSI) during active fermentation. Many brewers aim for 5–12 PSI on domestic equipment. This helps tame esters and boosts CO2 retention without stressing the yeast.

Plan your fermentation time WLP925 based on gravity, not the clock. White Labs suggests that final gravity is often reached in a one-week lager under warm, pressured conditions.

Monitor sulfur production closely. H2S may peak in the first 48 hours and usually fades by day five. This is important for gas-off and conditioning decisions to avoid trapped off-aromas.

After primary, condition at about 35°F (2°C) with roughly 15 PSI for 3–5 days. This short, cool period enhances clarity and mouthfeel before transfer or packaging.

- Use gravity readings as the definitive progress marker.

- Do not rely on pressure alone to confirm attenuation.

- Ensure pressure-safe fermenters and accurate spunding valves for safe control.

Adjust schedules if you follow warm pitch or traditional lager methods covered later in the article. Keep logs of temperature, pressure settings WLP925, and fermentation time WLP925. This will help refine future one-week lager attempts.

Pitch Rates and Yeast Management for Clean, Fast Ferments

Set your target based on wort gravity and fermentation style. For traditional lagers, aim near the industry lager pitch rate of about 2 million cells per mL per °Plato. For lighter worts up to 15°Plato, you can safely use around 1.5 million cells per mL per °Plato without sacrificing clarity or ester control.

Warm-pitch methods change the math. If you pitch WLP925 warmer, near 18–20°C (65–68°F), lag time shortens and yeast activity rises. This allows lower starting counts similar to ale rates, but you should still respect the WLP925 pitch rate guidance when planning a classic cold lager schedule.

Lab-grown formats shift expectations. PurePitch guidance and other proprietary formats often show higher viability and glycogen reserves. Packaged lab-grown yeast can be effective at lower inoculation numbers, with typical ranges of 7–15 million total cells per mL in those products. Always follow PurePitch guidance for those formats.

Repitching demands care. Measure viability and cell counts before reuse. Healthy yeast with good vitality reduces lag and cuts the chance of sulfur or diacetyl formation. If viability drops, raise your cells per mL per °Plato target to maintain fermentation speed and aroma control.

- Use a yeast calculator to size starters or pitched mass.

- Oxygenate properly at pitch to avoid stressed cells.

- Monitor nutrition and avoid prolonged oxygen exposure after pitching.

Practical steps for WLP925: when using high-pressure or warm-pitch approaches, expect faster fermentation and shorter conditioning times. Still calculate a conservative lager pitch rate when planning long, cold lagering to prevent sluggish finishes.

Track yeast health between generations. A fresh cell count and viability test let you adjust cells per mL per °Plato accurately. This helps maintain consistency and keeps off-flavors low across batches.

Preparing the Wort and Yeast for Optimal Performance

Begin wort preparation with a clean mash, ensuring the target Plato is achieved. Measure the original gravity, as higher values require more attention to pitch rates and nutrients. For worts up to 15°Plato, pitching at lower cell counts is feasible. However, stronger worts necessitate a larger yeast starter or fresh PurePitch to prevent slow fermentation.

Oxygenation for lagers is crucial, even under pressure. Ensure sufficient dissolved oxygen before chilling and pitching. This allows yeast to build biomass effectively. Use a calibrated aeration stone or pure O2 system to maintain consistent oxygen levels. This supports WLP925's reputation for a fast, clean start.

Plan your yeast starter WLP925 based on viability and target cells. Utilize White Labs’ pitch rate calculator or your lab data to determine starter sizes and step them up if necessary. A healthy starter minimizes lag time and enhances attenuation, typically in the 73–82% range, under optimal mash conversion and ferment conditions.

Consider adding nutrients for high-gravity worts or when oxygenation might be limited. Yeast nutrients prevent slow finishes and reduce off-flavor production. Administer measured doses early in fermentation, not at packaging, to support yeast health without upsetting balances.

Ensure transfers are closed and headspace is minimized in pressure fermentations to limit oxidation. Large, open headspaces in oversized fermenters increase oxidation risks. Employ sanitary, sealed lines and gentle transfers to safeguard aroma and flavor stability during and after pitching.

Remember, WLP925 is STA1 negative and lacks amylolytic activity. Attenuation will depend on mash profile and ferment conditions, not yeast starch conversion. Adjust adjuncts, mash temperatures, or pitch rate calculator results accordingly to reach your desired final gravity.

Practical Setup: Fermenters, Spunding Valves, and Pressure Control

Opt for a pressure-rated fermenter for reliable results. Stainless conical fermenters, converted Cornelius kegs, or purpose-built vessels are better than plastic buckets. They reduce oxygen entry and enhance consistency. Ensure the fermenter's pressure rating matches your target head pressure.

Utilize a spunding valve WLP925 to manage head pressure and capture CO2. Most brewers aim for 5 to 12 PSI. White Labs advises keeping pressure under 1.0 bar (14.7 PSI) to protect yeast and equipment.

Begin with 5–8 PSI settings to balance esters and carbonation. Adjustments depend on batch size, headspace, and gauge precision. Smaller vessels with large headspaces require different settings than nearly full tanks.

Use gravity readings alongside pressure monitoring. Pressure influences flavor and carbonation but cannot replace hydrometer or refractometer checks for fermentation progress.

Consider headspace and batch size. Large vessels can work if sealed properly. However, open headspaces or leaks increase oxidation risks. Homebrew forums highlight oxidation issues in undersized vessels and open buckets under pressure.

Adhere to safe pressure fermentation practices. Install effective pressure relief devices and confirm spunding valve calibration. Never exceed the vessel's rated PSI and check seals before pressurizing.

- Plan sampling to avoid contamination: use a plumbed port for closed draws or purge with CO2 before opening.

- Use a calibrated gauge and backup relief valve for redundancy.

- Record pressure, temperature, and gravity to refine future pressure fermenter setup decisions.

Proper setup minimizes risks and enhances control over WLP925 performance. Careful selection of fermenter pressure, accurate spunding valve settings, and safety measures make home pressure fermentation safe and effective.

Fermentation Schedules: Warm Pitch, Traditional, and Fast Lager Methods

Opt for a fermentation schedule that aligns with your availability, equipment, and desired flavor profile. Traditional lager fermentation commences at a cooler temperature, between 48–55°F (8–12°C). This method is preferred by those seeking a clean, refined taste. The process involves a gradual increase in temperature to around 65°F (18°C) during the diacetyl rest, which typically lasts two to six days. Following this, the temperature is gradually lowered by 2–3°C (4–5°F) per day until it reaches approximately 2°C (35°F).

The warm pitch lager schedule, on the other hand, starts at a warmer temperature, ranging from 60–65°F (15–18°C), and shows activity within 12 hours. Once fermentation begins, the temperature is reduced to 48–55°F (8–12°C) to minimize ester production. The diacetyl rest is conducted at 65°F (18°C), followed by a gradual cooling to lager temperatures. This method is advantageous as it reduces lag time and lowers the required pitch rate.

The fast lager method, utilizing WLP925, begins with a warmer temperature, around 65–68°F (18–20°C). It employs a spunding valve to maintain pressure. White Labs suggests keeping the pressure below 1.0 bar (approximately 14.7 PSI), although many brewers opt for 5–12 PSI for a faster, controlled fermentation. This approach can achieve terminal gravity in about a week, followed by a brief conditioning period at around 35°F (2°C).

- Traditional method: slower, very clean, needs higher pitch and patience.

- Warm pitch: balances speed and cleanliness while cutting cell-count needs.

- Fast high-pressure: throughput-friendly, needs careful conditioning to clear flavors.

WLP925 schedules can be adjusted based on the recipe, yeast health, and system pressure. For fast lagers, a week is typically needed to reach terminal gravity. Then, lager at 35°F (2°C) with light pressure for three to five days to enhance conditioning and clarity.

Pseudo-lager methods, using Kveik or other modern ale strains, ferment at ale temperatures without pressure. These alternatives produce different ester profiles and mouthfeel compared to the high-pressure WLP925 method. Therefore, selecting the right strain is crucial for achieving a lager-like taste.

Align your schedule with your objectives: choose traditional lager fermentation for delicate, classic lagers. Opt for a warm pitch lager schedule if you need fewer cells and quicker starts. For high-throughput and speed, the fast lager method with WLP925 is the best choice.

Dealing with Off-Flavors and Sulfur During Fermentation

When using White Labs WLP925 for lager fermentation, expect sulfur early on. The strain can release noticeable H2S WLP925 in the first two days. It's important to tolerate this smell initially and monitor its decrease by day five before assessing the beer's quality.

To manage diacetyl and avoid buttery notes, raise the fermenter's temperature to 65–68°F (18–20°C) at 50–60% attenuation. Alternatively, follow a free-rise approach to allow yeast to reabsorb diacetyl. This method is effective for traditional, warm pitch, and fast lager schedules.

Pressure fermentation is key in controlling esters and phenolics. Maintain consistent temperatures and consider warm pitching followed by a quick temperature drop. This approach helps reduce ester formation while ensuring a strong fermentation start.

Time and proper handling are crucial in sulfur mitigation. Allow H2S to volatilize or be reabsorbed by yeast. Note that pressure can trap volatiles early, so managing headspace and conditioning at cold temperatures promotes dissipation.

To prevent oxidation, minimize oxygen exposure during transfers. Closed, pressurized systems significantly lower oxidation risk. Small-volume ferments in large open buckets are more susceptible to stale flavors, as many homebrew forums suggest.

For accurate timing, rely on gravity readings and tasting, not pressure changes. A pressure drop does not confirm fermentation completion. Measure specific gravity before transfer and before lagering to confirm progress.

For practical off-flavor solutions, follow a checklist:

- Monitor early H2S and wait until it subsides before cold conditioning.

- Perform diacetyl management at mid-attenuation to allow reabsorption.

- Keep fermentations closed and reduce headspace during transfers to limit oxidation.

- Use sensory checks plus gravity readings to verify readiness for conditioning.

Conditioning and Lagering After Primary Fermentation

Once the yeast has reached the final gravity, it's time to condition at 35°F. This step is crucial for maturing the flavor and clearing the beer. White Labs suggests lagering WLP925 at around 35°F (2°C) under 15 PSI for three to five days. This promotes cold maturation and yeast settling.

Cold crashing WLP925 aids in dropping haze, reducing sulfur notes, and stabilizing aromas. A brief cold conditioning period encourages yeast to settle. If clarity is a top priority, consider using fining agents or extending the chill period.

Pressure conditioning at 15 PSI supports gentle carbonation and minimizes oxygen pick-up. However, beer under pressure may clear more slowly. If quick brightening is essential, use flocculent strains or finings before packaging.

- Account for carbonation: spunding adds CO2 during fermentation. Adjust target pressures to avoid overcarbonation when kegging or bottling.

- Minimize oxygen: perform closed transfers or purge lines with CO2 when moving beer from a pressurized vessel to kegs or bottles.

- Monitor gravity and aroma: confirm final gravity stability and taste profile before packaging. Allow extra conditioning time if sulfur or haze persist.

Cold crashing WLP925 and controlled pressure conditioning refine mouthfeel and aroma. Ensure clean fittings and steady temperatures to protect the beer during this delicate stage.

When packaging is ready, purge packages with CO2 and transfer with closed lines. This preserves the gains from lagering WLP925 and conditioning at 35°F. A careful finish minimizes the need for corrective steps after packaging.

Attenuation, Flocculation, and Alcohol Tolerance Expectations

White Labs indicates WLP925 attenuation at 73–82%. The final gravity will vary based on mash profile, fermentation schedule, and pitch rate. Aim for a mash and recipe that aligns your original gravity within this attenuation range.

Given the STA1 test results are negative for this strain, it cannot convert dextrins to alcohol. For higher attenuation, consider enzymatic methods or mash adjustments. This approach is more reliable than relying solely on the strain's capabilities.

Flocculation of WLP925 is classified as medium. This means beers will settle reasonably well, but under pressure, clarity might be slower. To enhance clarity, especially when bottling or kegging, use finings or a brief cold crash.

Alcohol tolerance for WLP925 is medium, ranging from 5–10% ABV. This makes it suitable for standard lagers and many adjunct styles. However, for very high-gravity lagers, blending with a higher-tolerance strain or employing a step mash with oxygenation is advisable to safeguard yeast health.

- Plan gravity targets to match WLP925 attenuation and alcohol tolerance WLP925.

- Adjust mash profile or add enzymes when higher attenuation is required.

- Expect medium flocculation WLP925; use clarifying steps for bright beer.

Before embarking on large batches, review yeast performance specs. Aligning recipe design with the strain's natural limits can prevent surprises and enhance consistency in your final product.

Recipe Ideas and Style Recommendations for WLP925

WLP925 excels in clean lager styles and malt-forward brews. For a classic pilsner, use Pilsner malt or high-quality US two-row. Add Saaz or Hallertau hops for a subtle noble character. Ferment at 62–68°F (17–20°C) for about a week. Then, condition at 35°F (2°C) with 15 PSI for 3–5 days to refine flavor and carbonation.

Helles or pale lagers benefit from WLP925 with minimal specialty malts. Keep hopping restrained for a crisp, clean profile. Aim for 2.4–2.8 volumes CO2 for a traditional mouthfeel. Be mindful of oxygenation and yeast nutrients, especially with adjuncts like rice or corn.

Amber lagers with WLP925 require Vienna or Munich malts for color and toasty notes. Target a balanced gravity under 10% ABV for the yeast's sweet spot. The standard WLP925 schedule produces a clean, malt-forward amber lager with restrained ester development.

For Märzen, Vienna, or darker lagers, build a deeper malt backbone. Use moderate specialty grains for caramel and biscuit. Proper oxygenation, steady pressure control, and a warm-to-cool transition are key to preserve clarity. Maintain moderate mash temps to support attenuation without stripping body.

Fast-lager or pseudo-lager approaches speed up production while maintaining quality. Start warm-pitch at 65–68°F (18–20°C) and use a spunding valve for fermentation under pressure. This method finishes in roughly one week, ideal for brewers needing quick turnaround without sacrificing clean flavor.

Adjunct-driven American lagers require careful handling. Rice or corn reduce available sugars for yeast; they do not activate STA1 to increase attenuation. Maintain oxygen levels and add yeast nutrients when needed. These recipes rely on strong yeast health to avoid stuck ferments.

Carbonation and final mouthfeel vary by style. Most styles suit 2.2–2.8 volumes CO2. Use pressure conditioning to fine-tune carbonation and creaminess. Small adjustments in pressure and resting time alter perceived body and hop lift in pilsner and amber lagers alike.

- Quick pilsner plan: Pilsner malt, Saaz hops, 62–68°F, pressure, 1 week primary, 3–5 days cold conditioning.

- Amber/Vienna plan: 80–90% base malt, 10–20% specialty malts, moderate hops, standard WLP925 schedule.

- Pseudo-lager plan: Warm pitch 65–68°F, spunding valve, finish in ~1 week, crash and condition under pressure.

These targeted suggestions help brewers choose the right grain bills, hopping rates, and fermentation paths. Use lager recipes WLP925 and the examples above to match yeast performance to the style you want to produce.

Common Troubleshooting Scenarios and Solutions

Sluggish or stuck fermentation with WLP925 can stem from various causes. These include low pitch rates, poor oxygenation, nutrient gaps, or excessive pressure. First, verify fermentation status by checking original and current gravity. If gravity remains unchanged after several days, try raising the fermenter temperature a few degrees to revive yeast activity.

If early in the process, providing a measured oxygen dose can help. If late, consider repitching a healthy, active lager yeast blend to complete attenuation.

Pressure fermentation issues often arise from over-pressurization or mis-set spunding valves. It's crucial to set spunding to a safe range, typically 5–12 PSI for lagers. Monitor gauges frequently to avoid overcarbonation. If beer becomes overcarbonated, vent to a safe pressure, chill to reduce CO2 solubility, then transfer or package once stable.

Always use pressure-rated vessels and calibrated gauges to prevent equipment failure.

Excess sulfur smells early in fermentation are normal with this strain. WLP925 produces noticeable H2S in the first 48 hours. Allow time for the sulfur to clear during active fermentation and the first days of conditioning. If sulfur persists at packaging, extend cold conditioning or perform gentle rousing of yeast while temperatures are still suitable to help reduction.

For stubborn cases, activated carbon polishing can remove remaining sulfur before packaging.

Oxidation risk increases when brewing small batches in oversized fermenters with large headspace. Minimize headspace, purge vessels with CO2, or use closed, pressure-rated fermenters to lower oxygen contact. Transfer carefully during packaging and avoid splashing to preserve bright, clean flavors in lagers.

Poor clarity while fermenting under pressure can be frustrating. Beer under pressure often drops yeast more slowly. Use finings, extended cold lagering, or light filtration to speed clarity. If clarity is a frequent target, select more flocculent yeast or harvest and repitch yeast to encourage faster settling in future brews.

Do not assume pressure rise equals attenuation. Misreading pressure as fermentation progress leads to bad timing. Always confirm final gravity with a hydrometer or a refractometer corrected for alcohol to verify true attenuation before packaging or lagering.

- Check gravity before taking corrective action for stuck fermentation WLP925.

- Maintain spunding valves within recommended PSI to avoid pressure fermentation issues.

- Allow time and cold conditioning to handle early sulfur production as one of the lager off-flavors solutions.

- Minimize headspace or purge with CO2 to prevent oxidation in small-volume brews.

Conclusion

White Labs WLP925 High Pressure Lager Yeast offers brewers a clear advantage. It allows for faster lager production without compromising on the clean taste. This yeast's steady attenuation (73–82%), medium flocculation, and 5–10% alcohol tolerance make it ideal for Pilsner to Schwarzbier styles. It's particularly effective when used in pressure-capable vessels.

Its best applications include warm-pitch or traditional lager schedules. Positive pressure (5–12 PSI) is used to suppress esters and speed up fermentation. This yeast can achieve rapid FG in a week at 62–68°F under about 1.0 bar. It also produces a cleaner flavor when started at warmer temperatures.

However, brewers should be aware of some operational caveats. It's crucial to control pitch rates, oxygenation, and conditioning to avoid issues with stalled or reduced clarity. Following White Labs' temperature and pressure guidelines is essential. Monitoring gravity closely and conditioning at low temperatures (around 35°F / 2°C) with recommended pressure is key. This yeast is recommended for both commercial and home setups looking to shorten lager timelines while maintaining classic lager character.

Further Reading

If you enjoyed this post, you may also like these suggestions:

- Fermenting Beer with CellarScience Kölsch Yeast

- Fermenting Beer with CellarScience Baja Yeast

- Fermenting Beer with Fermentis SafAle S-33 Yeast